1-1/2 Inch Service Wrench

1-11/16 Inch Service Wrench

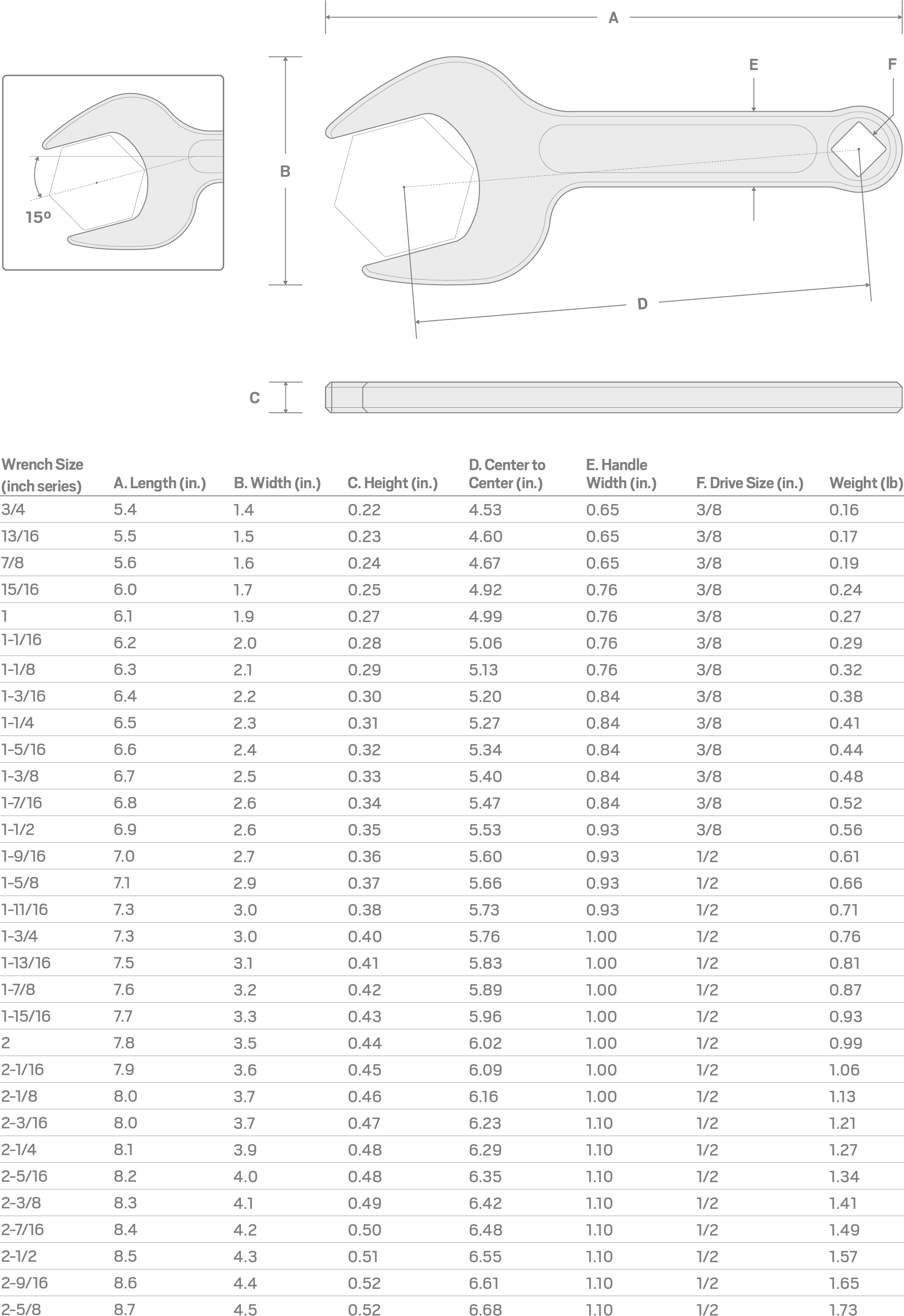

Details

Ideal for Hydraulic Lines

Part of a System of Access Wrenches

Service Wrench Design Features

A. Tapered Tips

A 10º lead-in taper on both of the tips helps the jaws fit over painted, dirty, or corroded fittings.

B. Tight Jaw Tolerances

Wrenches are cut from plate steel and then CNC milled on every surface, including the jaws. The final jaw tolerances are more exact than the ASME standards.

C. 15º Angled Head

The head is turned to a 15º angle, rather than the conventional 30º, to offer optimal access positions on a hex fitting.

D. Uniform Finish

The surface of the wrench is abrasive-blasted to create a smooth satin texture. The nickel finish is uniformly applied using an electroless plating process.

E. Strong, Well-Proportioned Handle

The non-tapered handle has a uniform thickness, a 45º outside chamfer, and a finger pocket on both sides for a more comfortable and secure grip.

F. Pommel

The pommel at the end of the handle keeps your hand from slipping off and is rounded for comfort.

G. Drive Square

The drive square can be used with a ratchet or other drive tools to increase access or leverage and apply specific torque. Four detent grooves secure the connection.

H. Engraved Torque Adapter Measurement

The distance between the center of the drive square and the center of the hex fastener is engraved on the handle for quick reference when using the wrench as a torque adapter.

Drive Square Capabilities

Secure Retention for Drive Tools

Reach Farther and Get More Leverage

Work Around Obstacles at Any Angle

Extend Into Confined, Recessed Areas

Torque to Specification

Thin Jaw for More Access

Tapered Tips

4140 Steel, Satin Nickel Finish

Electroless Nickel Plating

Electroless Nickel Plating Conventional Chrome Plating

Conventional Chrome PlatingUniform Coverage and Better Fit

Manufactured in Michigan

Specifications

1-1/2 Inch Service Wrench

| Country of Origin | United States |

| Item Weight | 0.56 lb. |