WRENCHES

Our System of USA-Made Access Wrenches

Published 6/3/2025

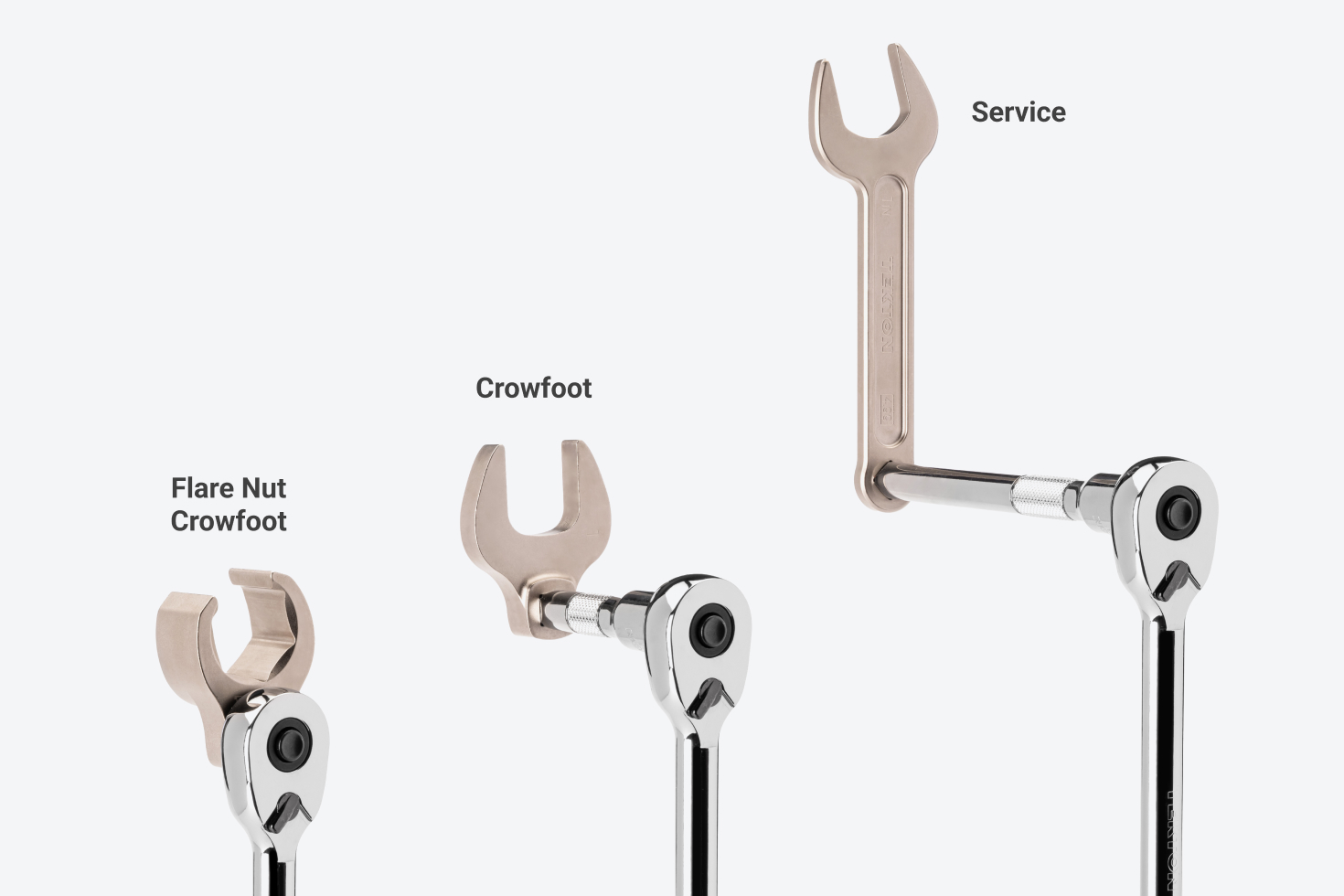

We offer four types of wrenches designed for versatile access in tight spaces: crowfoot wrenches, flare nut crowfoot wrenches, service wrenches, and angle head wrenches. They won’t replace your go-to combination wrenches, but when working on equipment in confined areas, especially around hydraulic lines and manifolds, these wrenches can be big time savers.

Tight access requires precision, so small differences in jaw angle, handle length, and head thickness matter. Each wrench excels in different scenarios, but they all share a similar manufacturing process in Michigan, with most of the steps taking place in-house at our Grand Rapids facility.

Key Advantages of Each Wrench

Crowfoot Wrenches

Tekton crowfoot wrenches are ultra-compact and designed to pair with a ratchet, which lets you set the wrench head to any angle. Add an extension to maintain its small swing radius and access recessed areas where other wrenches won’t fit or get enough swing clearance. You can also use them with a torque wrench. They’re not the fastest wrenches to turn, but sometimes they’re the only ones that will fit.

Flare Nut Crowfoot Wrenches

Tekton flare nut crowfoot wrenches can fit over hard line tubing and get five points of engagement on soft metal fittings, rather than two points of engagement with regular open end crowfoot wrenches. They have a leaner jaw for better access when fittings are crowded together, and deep walls for added strength. They can also be used with a ratchet and extension or a torque wrench.

Service Wrenches

Tekton service wrenches excel in situations with medium access and are fast and efficient to turn fittings by hand. They have a 15º angled head and short handle with a drive square at the end. Pair them with a ratchet and extension or a torque wrench for more versatility. They have the thinnest and leanest jaws of any open end wrench we offer, allowing them to squeeze between tightly-spaced fittings.

Angle Head Wrenches

Tekton angle head wrenches offer the quickest way to turn a fitting or fastener in situations where swing arc is restricted and the surrounding space allows for the longer handle. They have two heads of the same size, with 30 and 60-degree angles, achieving four unique access positions on a single set of hex flats. The slim handle beam is aligned to the outside jaw of each head, allowing the wrench to wrap around obstructions and maximize swing arc.

Feature Comparisons

All eight examples below use 1 inch wrenches for equal comparison.

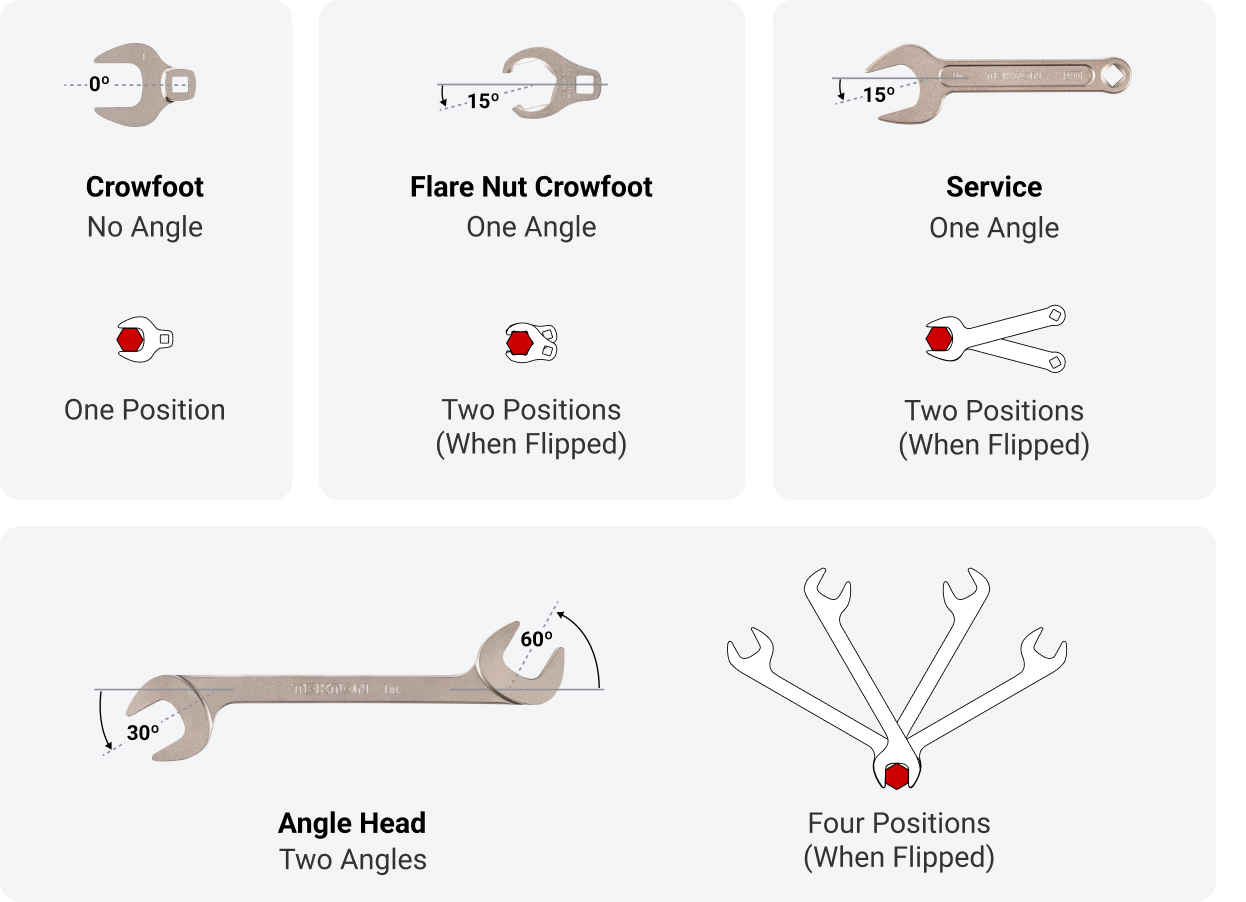

1. Head Angles and Handle Positions

If swing arc is limited by obstacles, a wrench with an angled head can be useful—it can be flipped to gain another access position. Angle head wrenches with 30° and 60° heads allow multiple flip options, giving you four unique handle positions on a single set of hex flats.

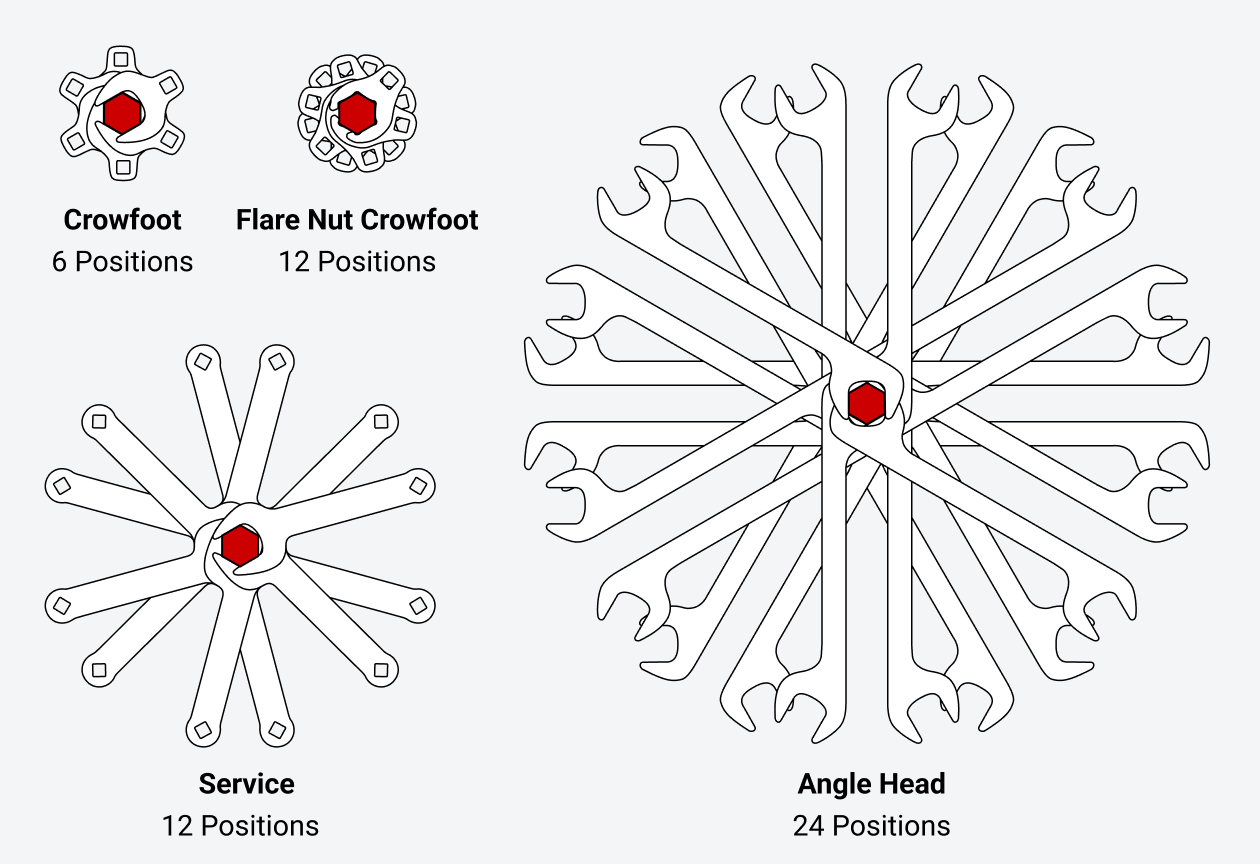

2. Access Coverage Around a Hex

Of the two crowfoot wrenches, the flare nut style can be flipped over, moving the drive square buckle out of the way and gaining twice as many access positions around a hex.

Of the two handled wrenches, the angle head wrenches offer twice as many access positions, with a more even distribution of space between them.

Of the two handled wrenches, the angle head wrenches offer twice as many access positions, with a more even distribution of space between them.

3. Working Radius

If you’re working in tight spaces, crowfoot wrenches can be used with an extension to achieve the smallest possible swing radius. Service wrenches are the next-best option if space allows, because they are significantly shorter than angle head wrenches.

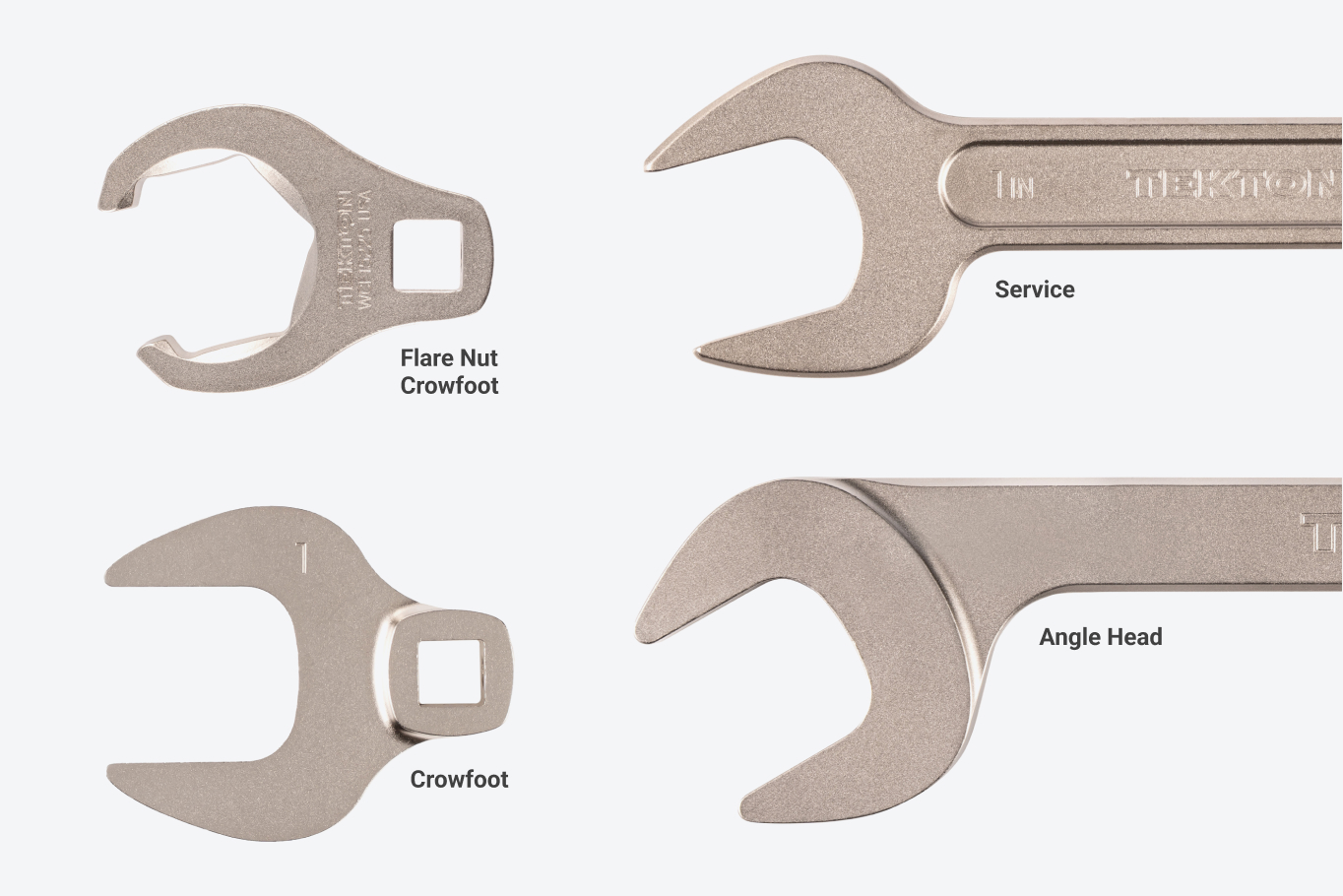

4. Jaw Profile

The service wrench has the leanest jaw of all the open end access wrenches, but the flare nut crowfoot wrench has the leanest jaw overall.

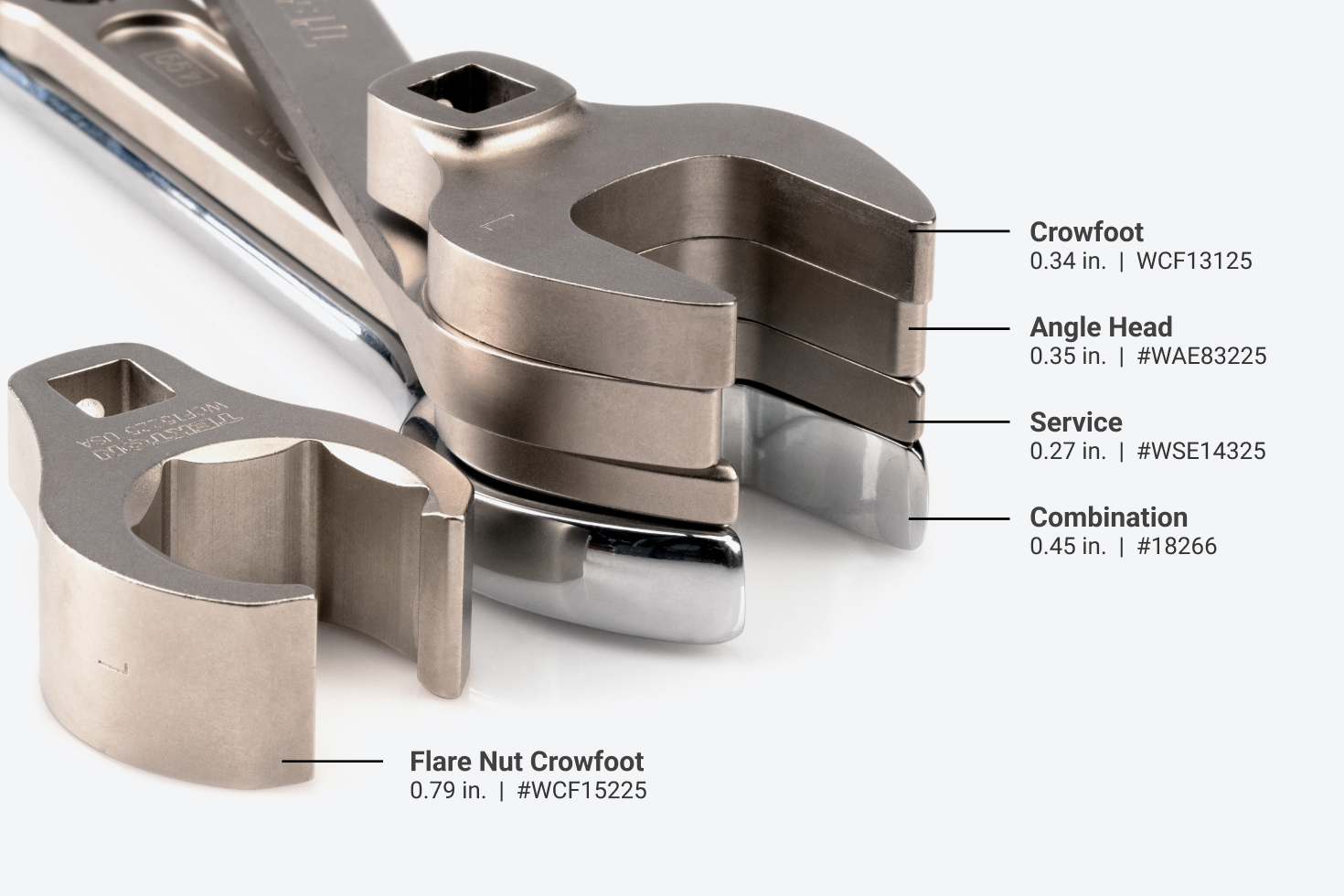

5. Jaw Thickness

Three of our access wrenches are thinner than our combination wrenches. Service wrenches have the thinnest jaws of all our open end access wrenches. Crowfoot and angle head wrenches are similar to each other in thickness. Flare nut crowfoot wrenches have a deep well for added strength, making them the thickest.

View Jaw Size Comparison Chart (PDF)

View Jaw Size Comparison Chart (PDF)

6. Drive Tool Options

Both crowfoot wrench styles and service wrenches have a drive square to pair with ratchets and other drive tools that can be used to extend your reach, work around obstacles, and gain extra leverage.

7. Precision Torque

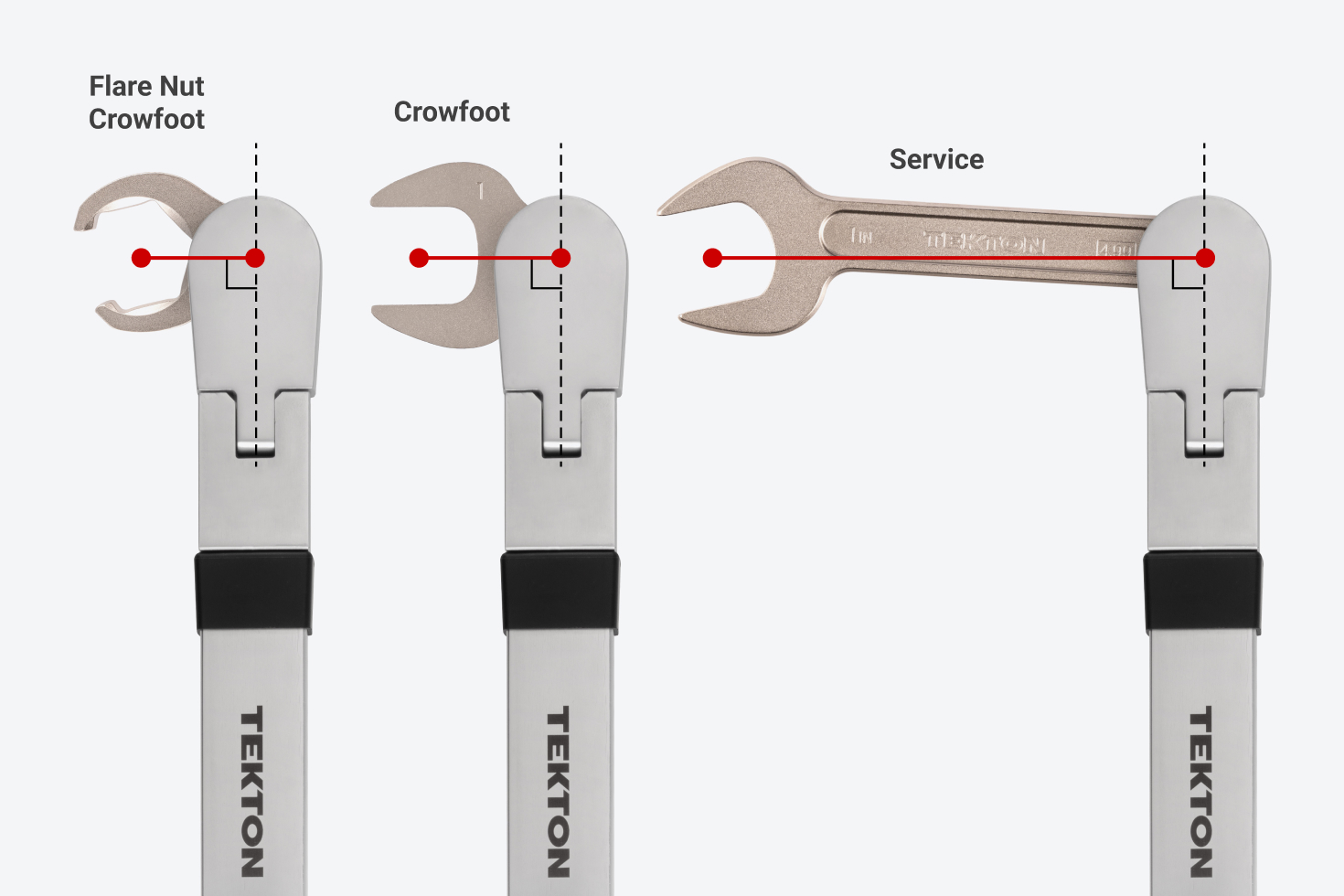

If you need to tighten fasteners or fittings to a specific torque, crowfoot and service wrenches can be used with a torque wrench. For the service wrench, note that the center of the drive square opening is off-axis from the center of the hex opening.

We offer a Torque Conversion Calculator to properly use these wrenches at any angle other than 90°.

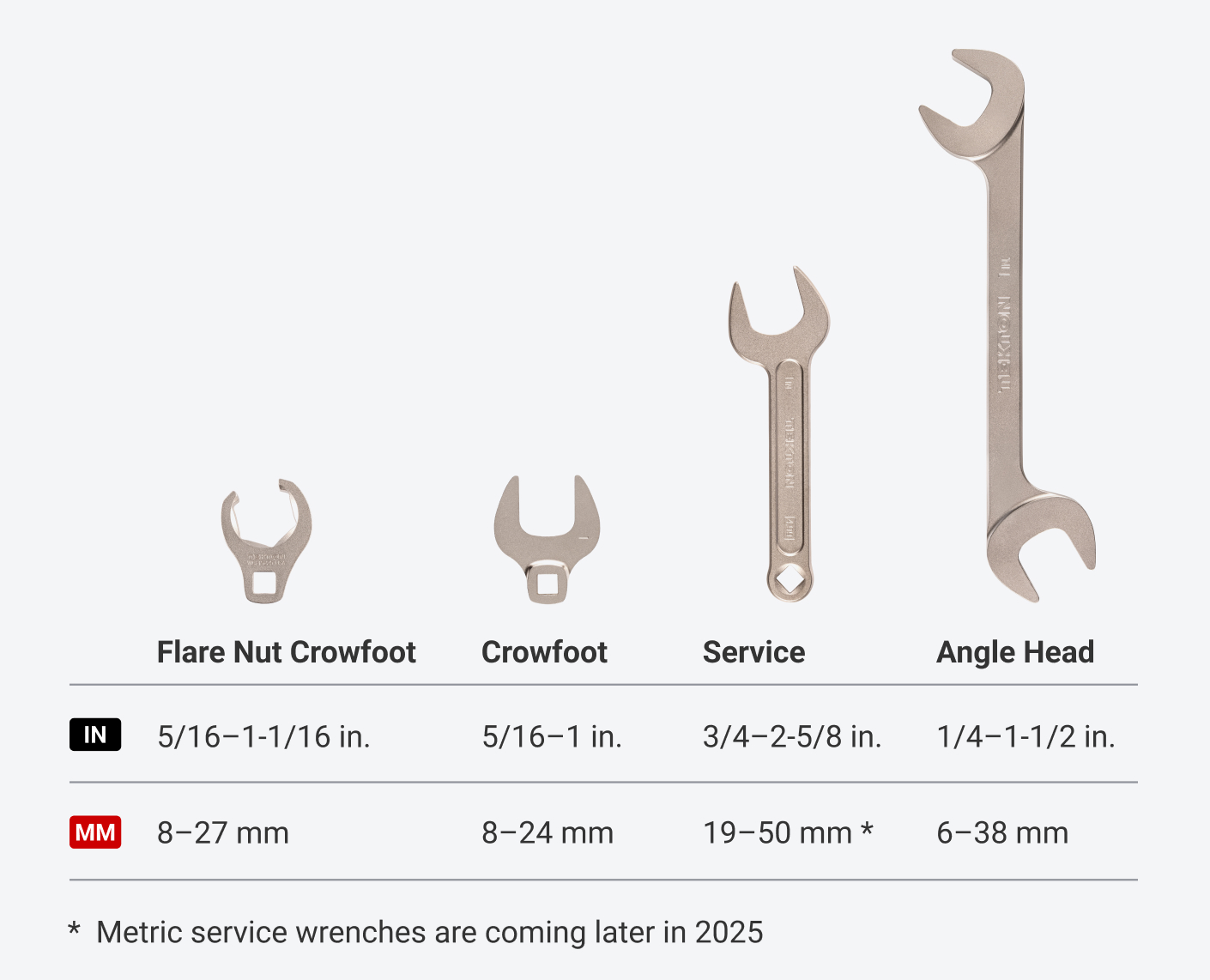

8. Size Range

If you need access wrenches larger than 1-1/2 in. or 38 mm, service wrenches are currently your only Tekton option (metric sizes are coming). For anything smaller, angle head wrenches offer the widest range.

View Size Range Comparison Chart (PDF)

View Size Range Comparison Chart (PDF)

Manufactured in Michigan

All four access wrenches are manufactured in Michigan using similar processes. Most of the steps occur in our Grand Rapids facility, where we machine, laser mark, vibratory polish, abrasive blast, and nickel plate each wrench.

Shop All Access Wrenches

Most points of engagement with fittings on hard lines in tight spaces