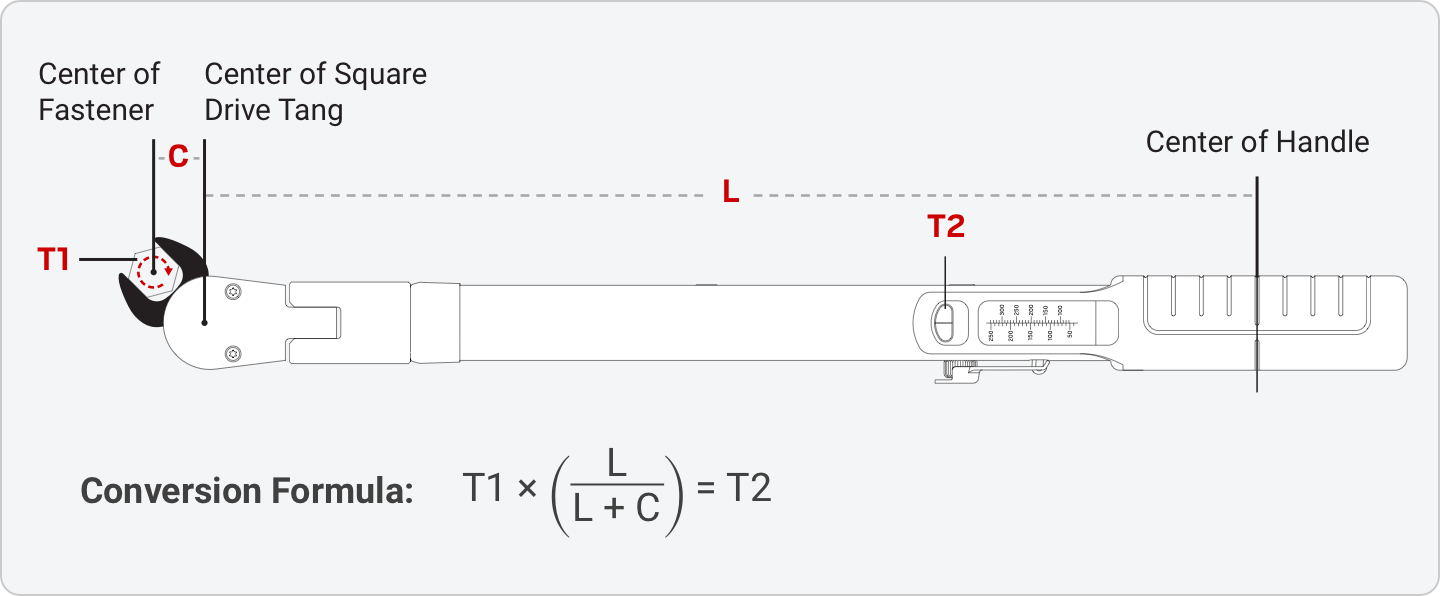

The diagrams above show a representative sample of a Tekton split beam-style torque wrench. The formula assumes that the head and handle of the torque wrench are straight and that the flex head, if present, is not engaged.

Formula Inputs

T1 – Torque specification for the fastener.

L – Effective length of the torque wrench. Measure from the center of the square drive tang to the indicator line on the handle of your Tekton torque wrench. First, set the torque wrench to the torque spec for the fastener (T1) and then measure in a straight line parallel to the body of the wrench. Most Tekton micrometer torque wrenches have a groove in the knurled handle grip. Tekton split beam torque wrenches have a line in the center of the handle. (For other brands of torque wrenches, check the manufacturer recommendations, or use the center of the handle grip if the manufacturer does not recommend a location).

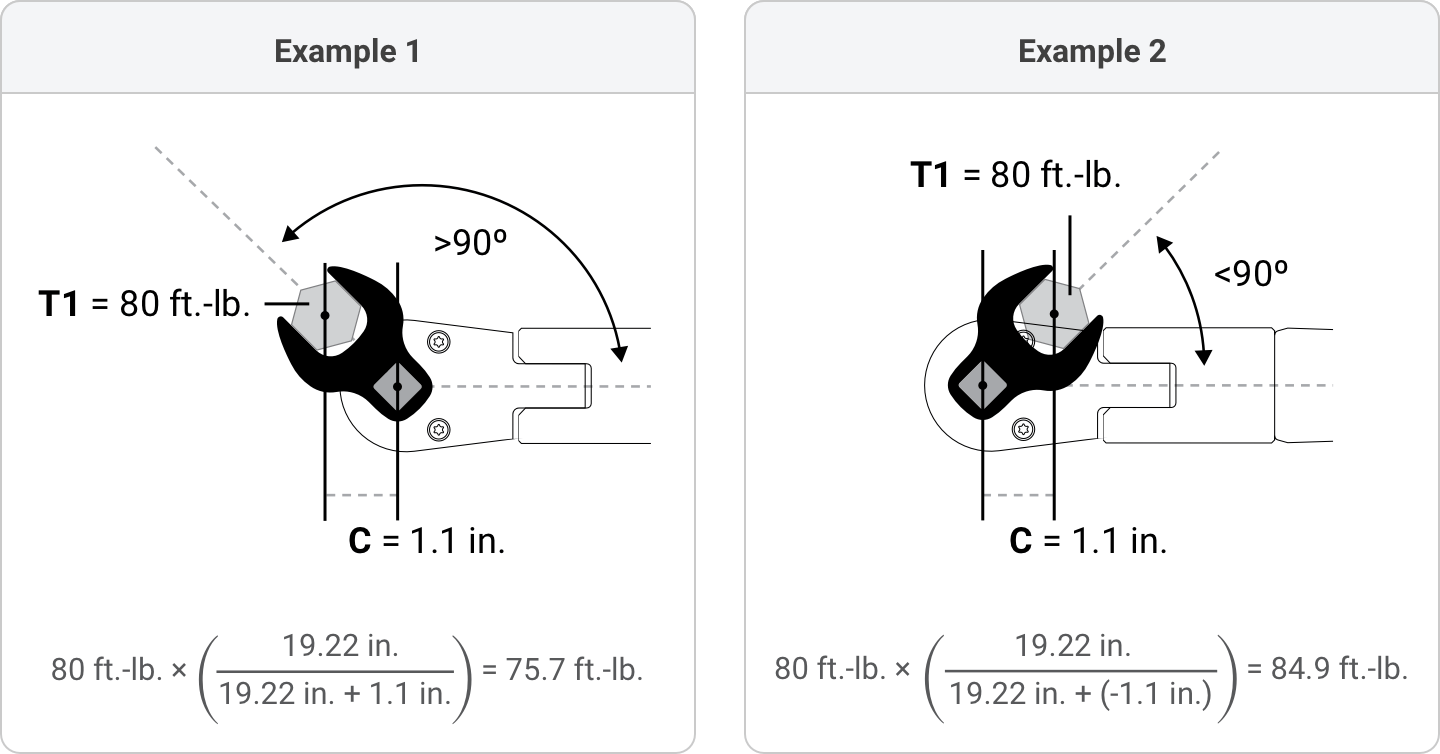

C – Change in length caused by the crowfoot wrench. Measure from the center of the fastener to the center of the square drive tang on the torque wrench. Measure in a line parallel to the body of the wrench. If the position of the crowfoot wrench decreases the effective length of the torque wrench, creating a negative change, then input this amount into the equation as a negative number.

Formula Output

T2 – Final torque wrench setting that you should use. This will correct for any change in leverage caused by using the crowfoot wrench.

TERMS OF USE:

By using the Torque Conversion Calculator, you agree

that you alone are responsible for the conversion calculation, torque wrench setting, and any actual

application of the conversion calculation.