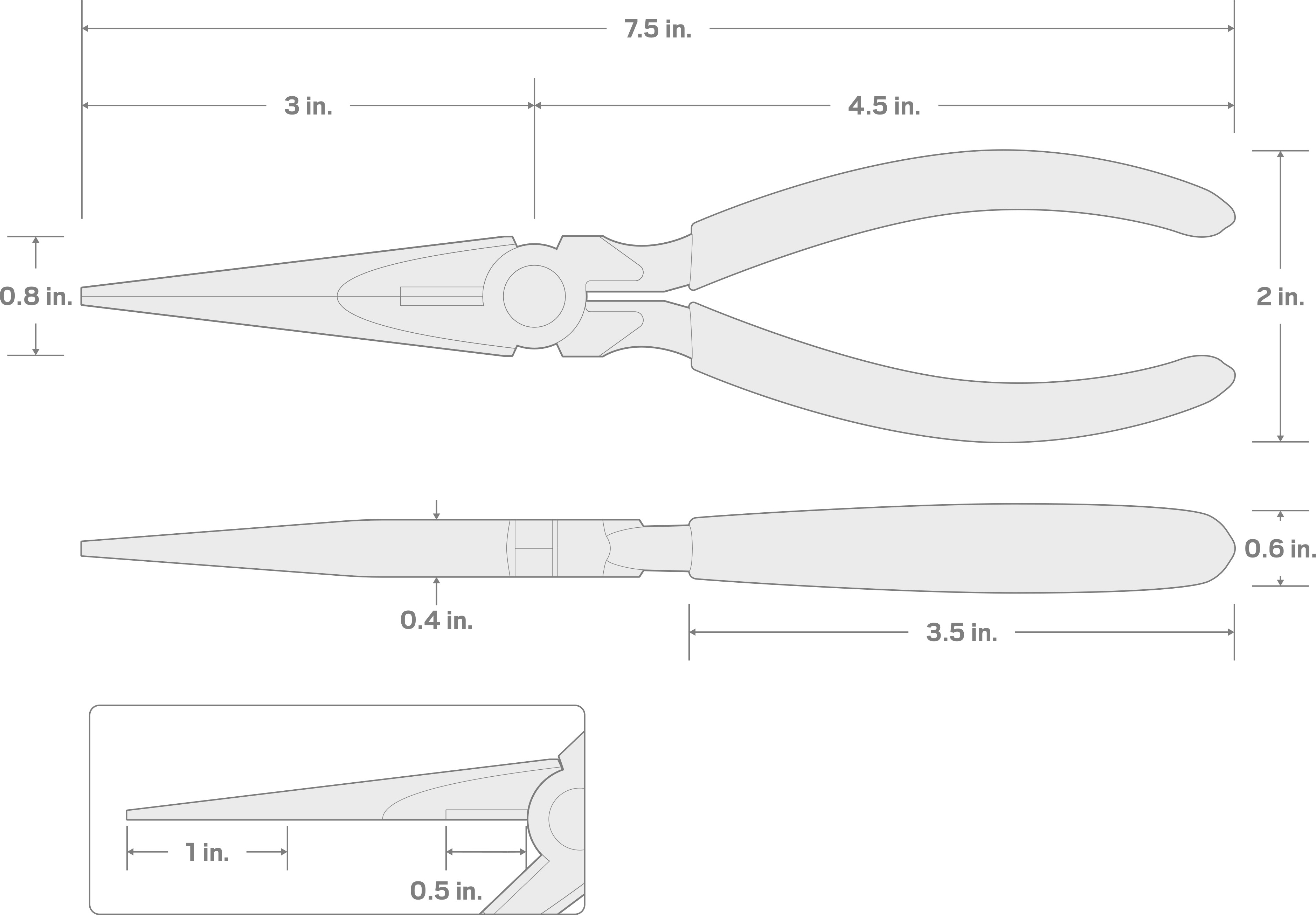

7 Inch Serrated Jaw Long Nose Pliers

7 Inch Serrated Jaw Long Nose Pliers

- Long, tapered nose with fine tip

- Crosscut teeth distribute force evenly for sure grip in any direction

- Wire cutter cleanly snips copper, aluminum, and other soft metals

- Wide, flat handles with slim, nonslip grips provide comfortable fingertip control

Details

An extra long, slender nose and 1/2 inch side cutters make these pliers ideal for repairing vehicle electrical systems, installing or upgrading equipment or machine controls, and assembling larger RC kits. |  |

An extra long, slender nose and 1/2 inch side cutters make these pliers ideal for repairing vehicle electrical systems, installing or upgrading equipment or machine controls, and assembling larger RC kits.

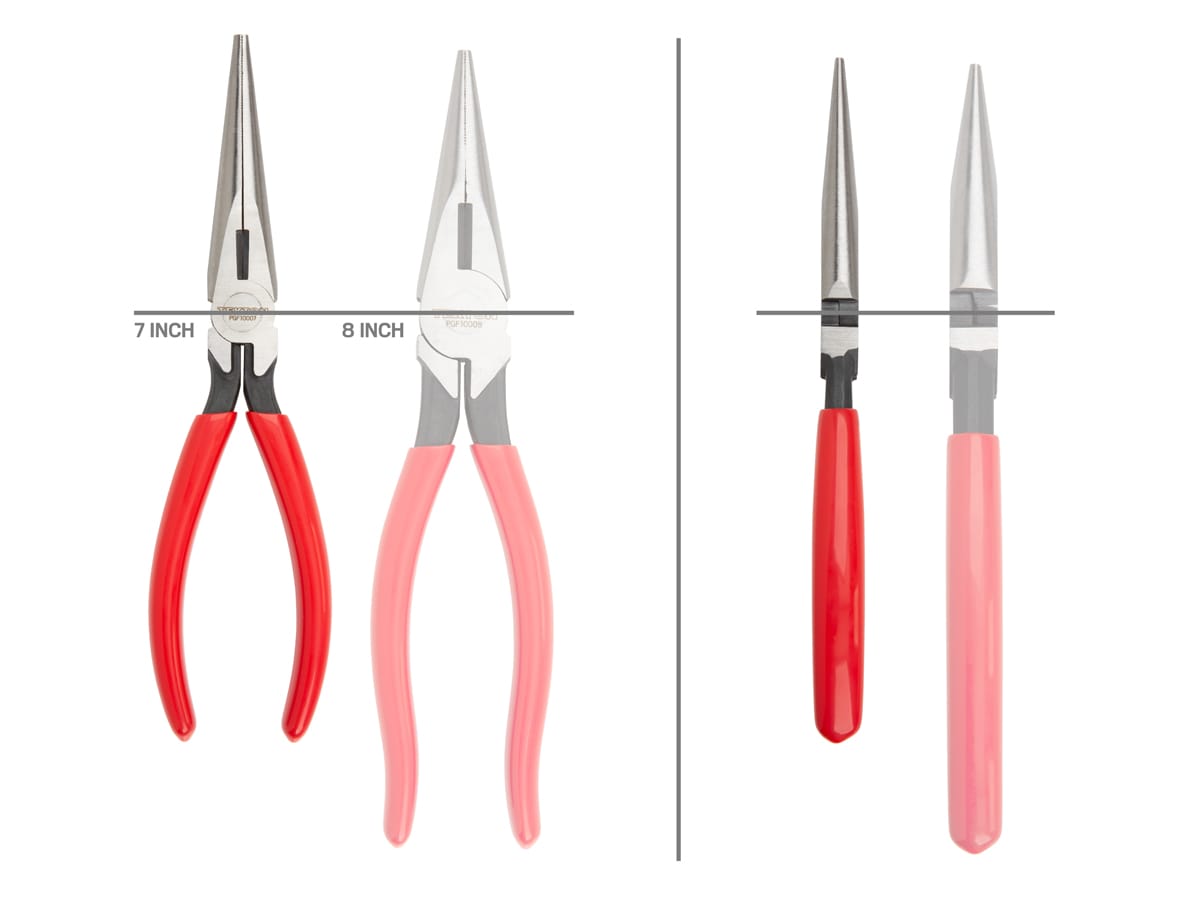

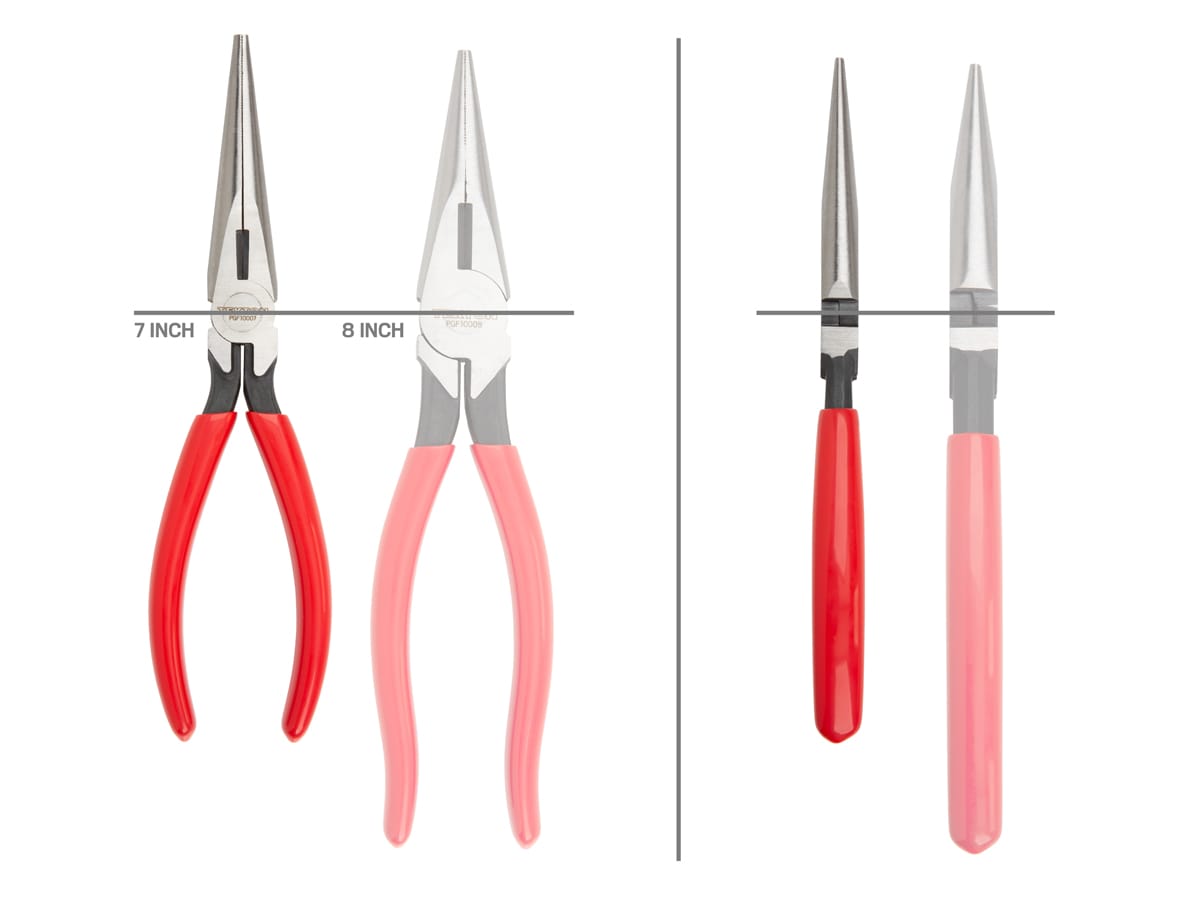

Light and ManeuverableSignificantly slimmer than our 8 in. Long Nose Pliers, these pliers are thin and sleek throughout, light and exceptionally maneuverable. |  |

| Extended Reach into Tight SpacesRelative to its overall length, these pliers have an extra long and slender nose that reaches deep into tight spaces and offers a deft grasp on small parts. |

Light and Maneuverable

Significantly slimmer than our 8 in. Long Nose Pliers, these pliers are thin and sleek throughout, light and exceptionally maneuverable.

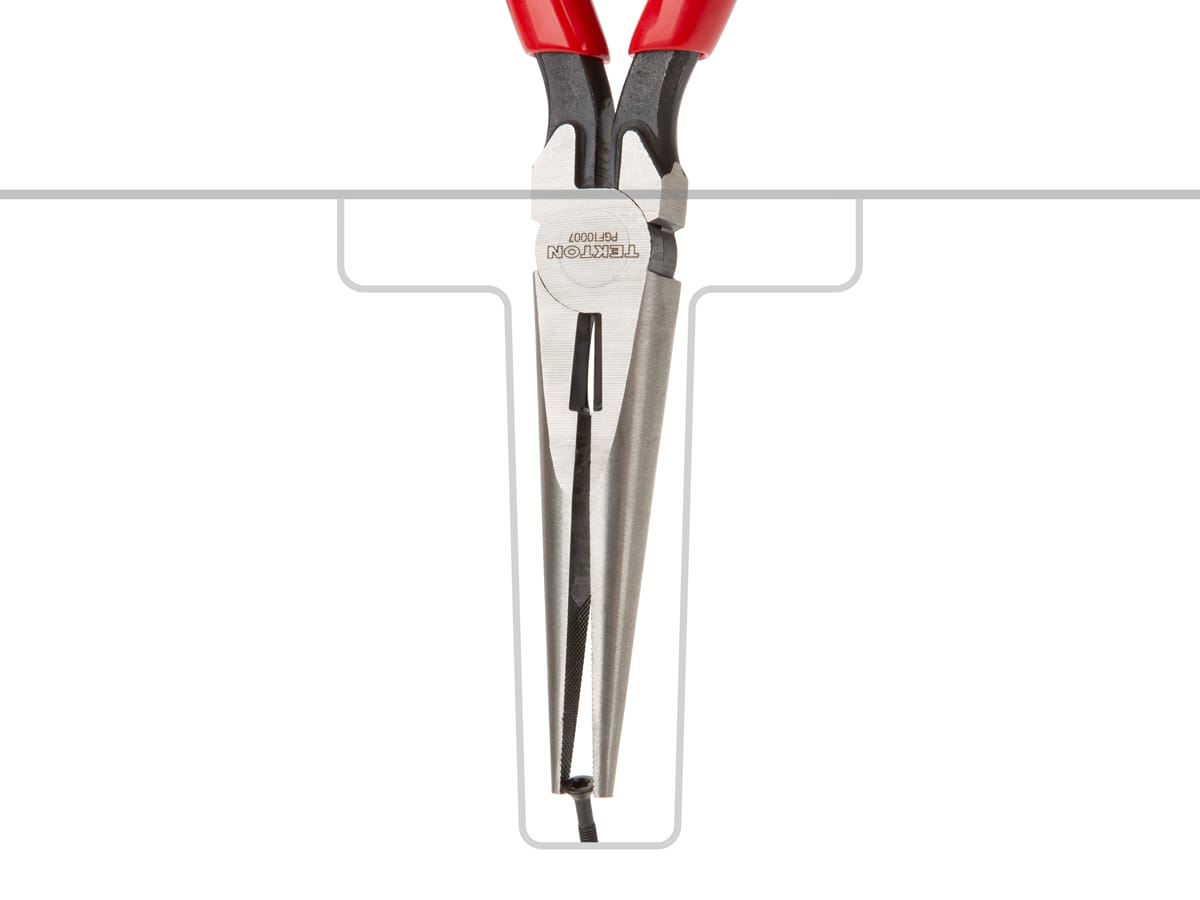

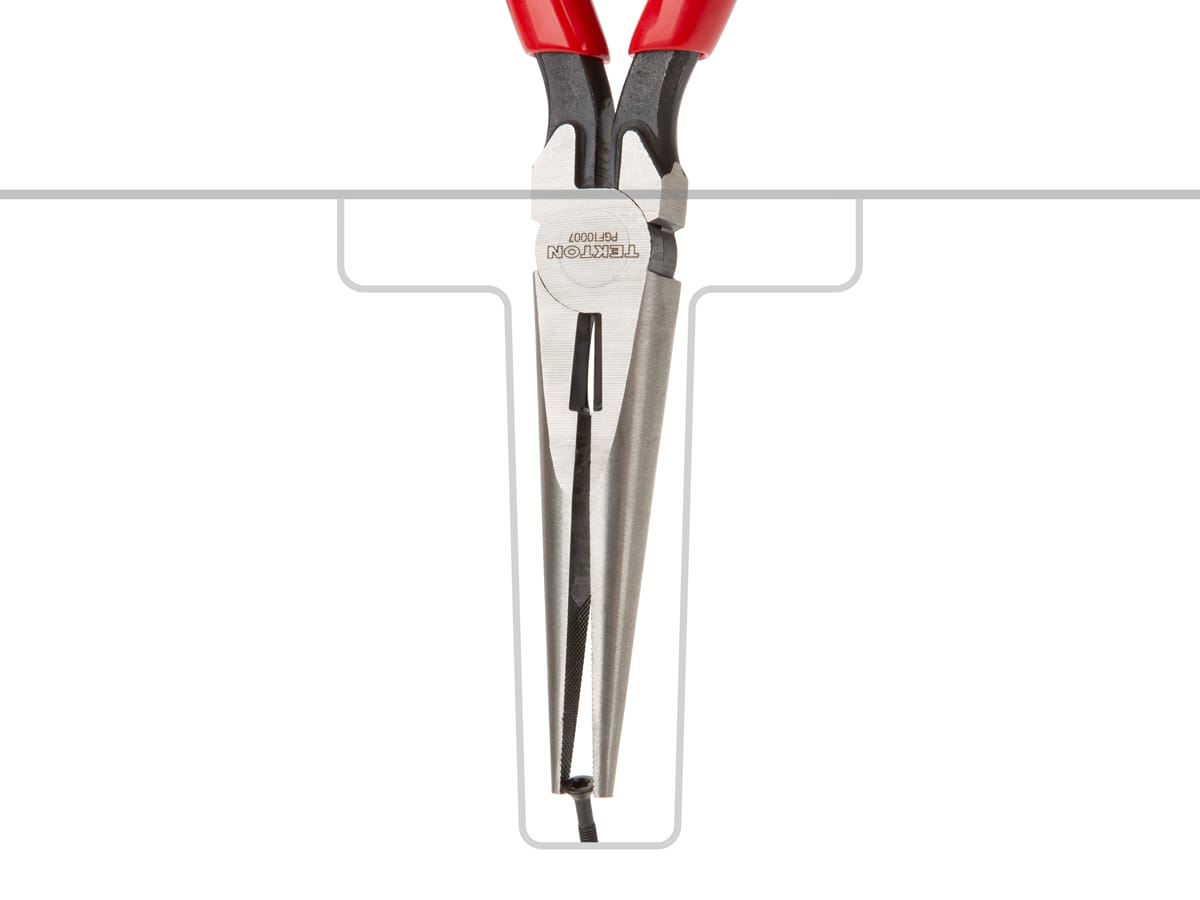

Extended Reach into Tight Spaces

Relative to its overall length, these pliers have an extra long and slender nose that reaches deep into tight spaces and offers a deft grasp on small parts.

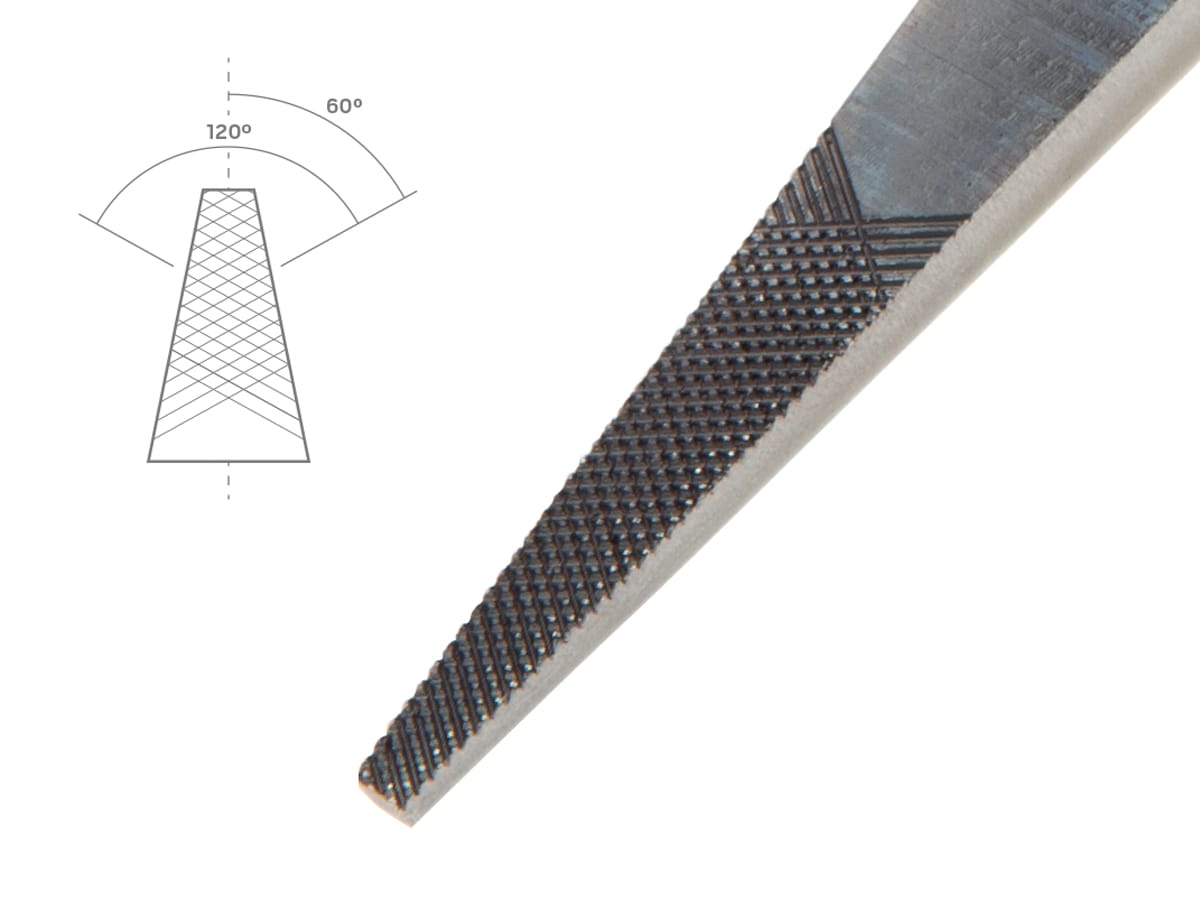

Crosscut Teeth

Oriented at 120 degrees to each other, the serrations are cut in two passes to form regularly-spaced, diamond-shaped teeth.

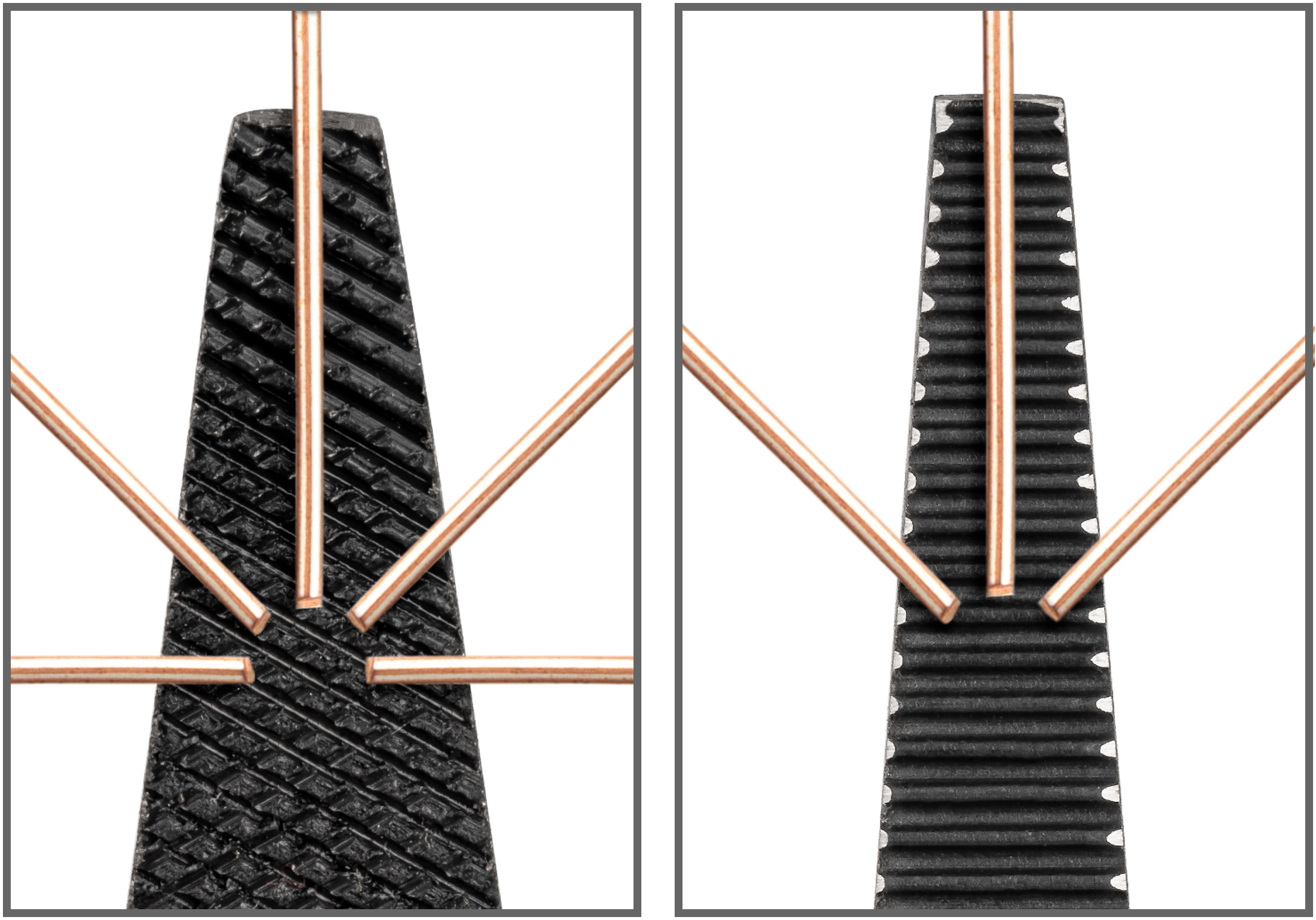

Grip in All Directions

Unlike straight serrations where the grip strength varies relative to tooth direction, a crosscut pattern grips evenly in any direction.

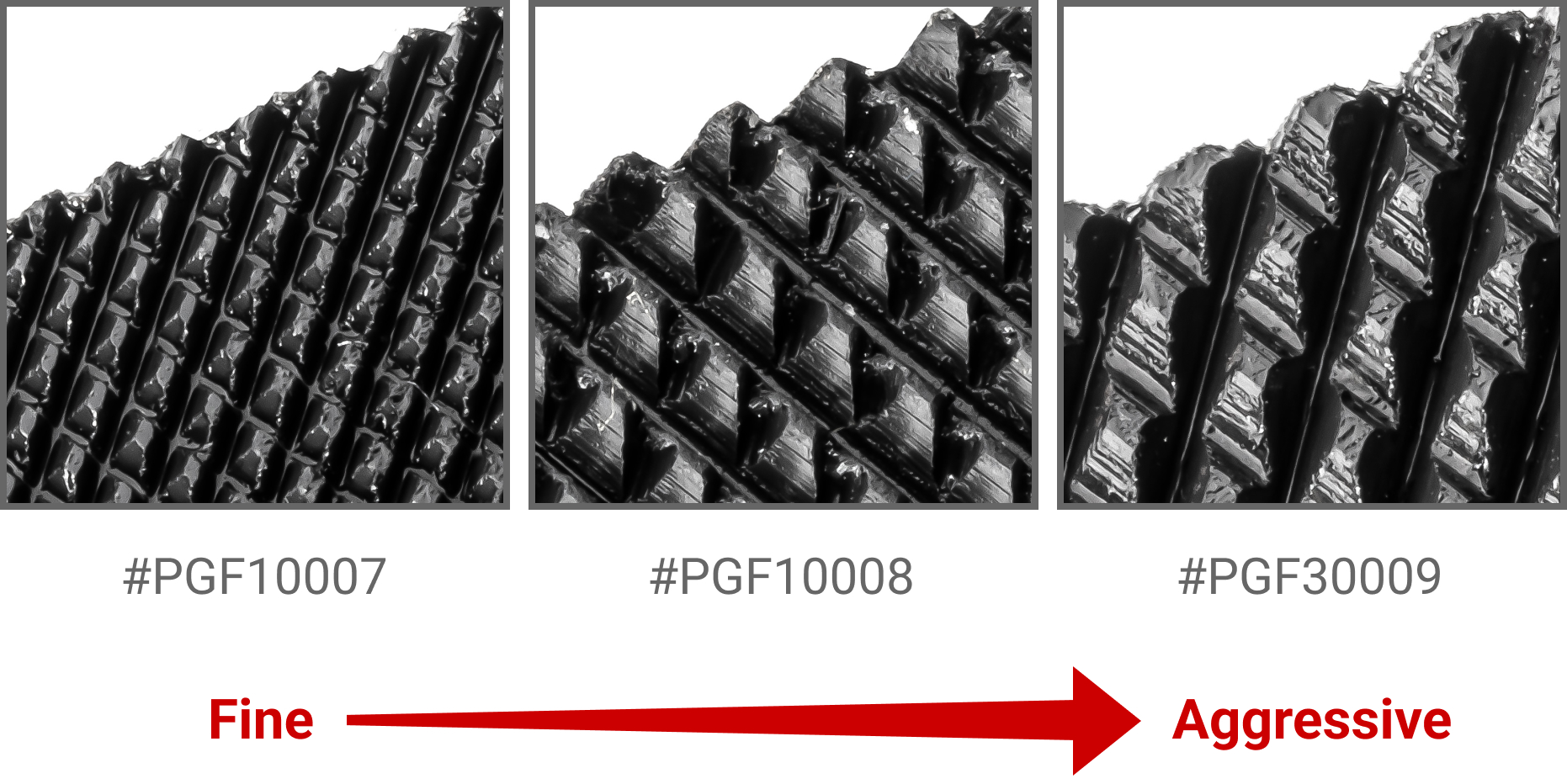

Range of Tooth Types

Smaller pliers with fine teeth are best for smaller precision applications and result in less marring of the work piece. Larger pliers with more aggressive teeth provide a stronger grip on less delicate parts.

Clean Cut with Minimal Effort

Machining the blades to an optimized 65-degree angle allows them to be strong yet sharp, producing a satisfyingly smooth, clean cut that requires minimal effort.

INDUCTION HARDENED

After the full pliers have been heat treated, a secondary induction-heating process hardens just the blades to 58-64 HRC, making them extremely durable and able to cut tougher materials.

KNIFE-TO-KNIFE

Comprised of two opposing blades that meet in the center, it is an extremely reliable cutting method, especially for harder wires. For a clean, low-effort cut, it requires a high level of manufacturing expertise to produce the near perfect alignment of the blades. When this cannot be consistently achieved, some manufacturers may turn to a less effective knife-and-anvil design (one knife blade, one blunted blade) that doesn't require such precise alignment.

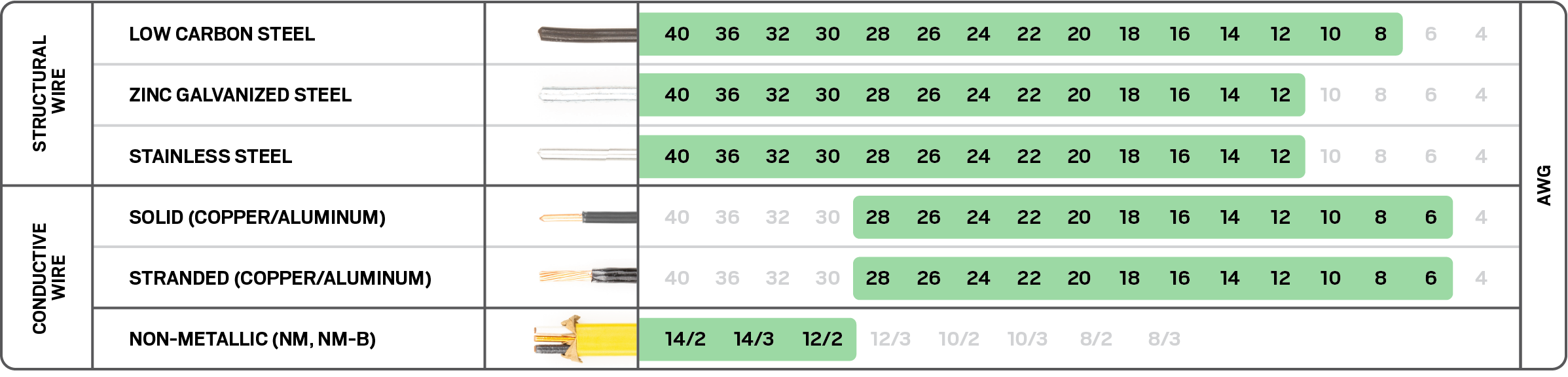

Cutting Capacities

Lean and Practical GripsSingle-layer vinyl grips offer a bit of comfortable cushion and provide a smooth, yet nonslip surface. They're slim, not thick and bulky, so they stay out of the way when space is tight and are always easy to handle, even with gloves on. |  |

Lean and Practical Grips

Single-layer vinyl grips offer a bit of comfortable cushion and provide a smooth, yet nonslip surface. They're slim, not thick and bulky, so they stay out of the way when space is tight and are always easy to handle, even with gloves on.

Non-absorbing and resistant to most common fuels, lubricants, and cleaners. Won't get soft or sticky over time. Easy to wipe clean.

Specifications

7 Inch Serrated Jaw Long Nose Pliers

| Country of Origin | Taiwan |

| Item Weight | 0.36 lb. |