1/2 Inch Drive 90-Tooth Electronic Torque Wrench

1/2 Inch Drive 90-Tooth Electronic Torque Wrench

| Drive Size | 1/2 in. |

|---|---|

| Tooth Count / Swing Arc | 90-Tooth / 4º |

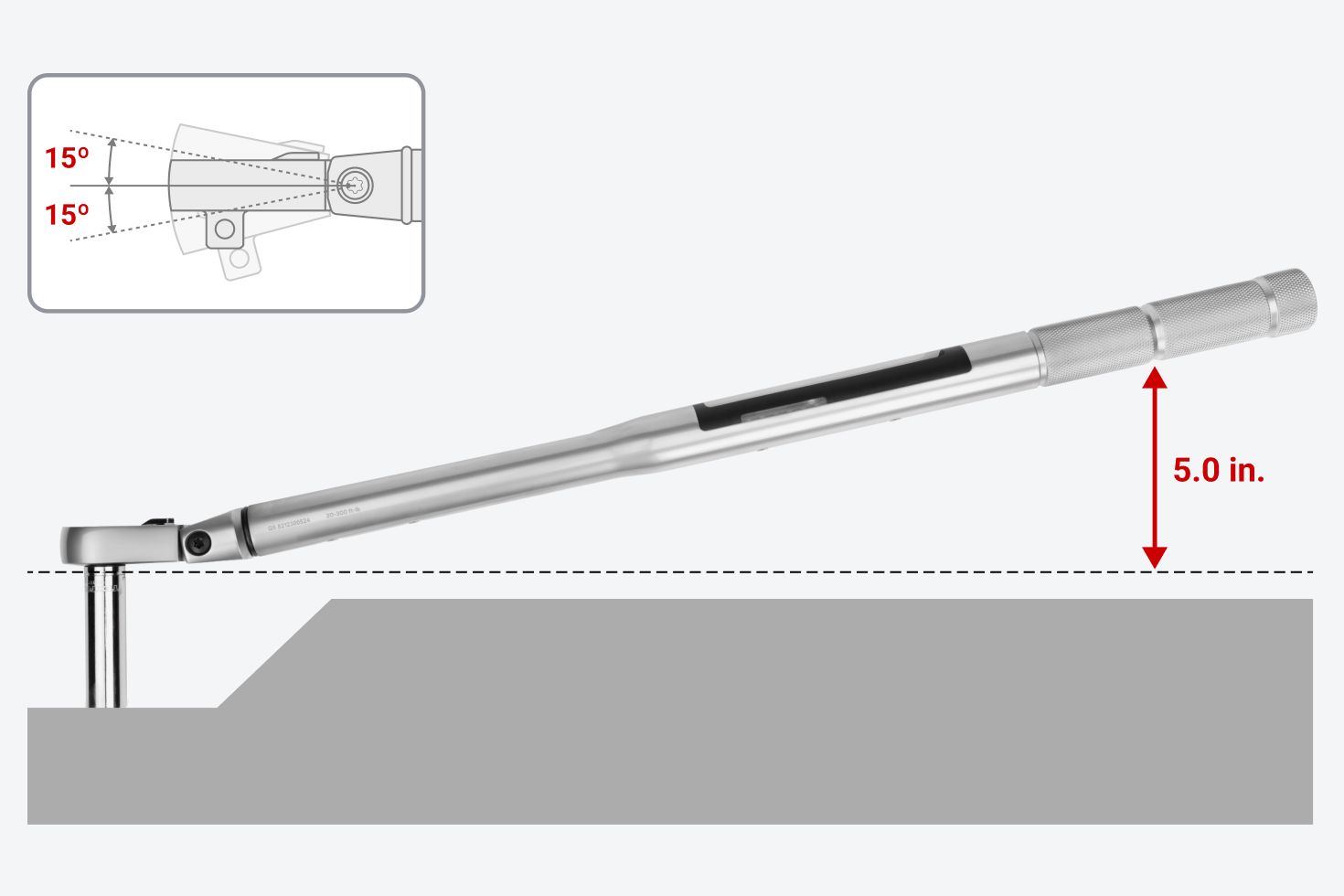

| Head Style | 15° Flex |

| Torque Range | 30 - 300 ft-lb |

| Torque Calibration Test Points | 30, 180, 300 ft-lb |

| Unit Scale | in-lb, ft-lb, Nm, kg-m |

| Minimum Increment | 1 |

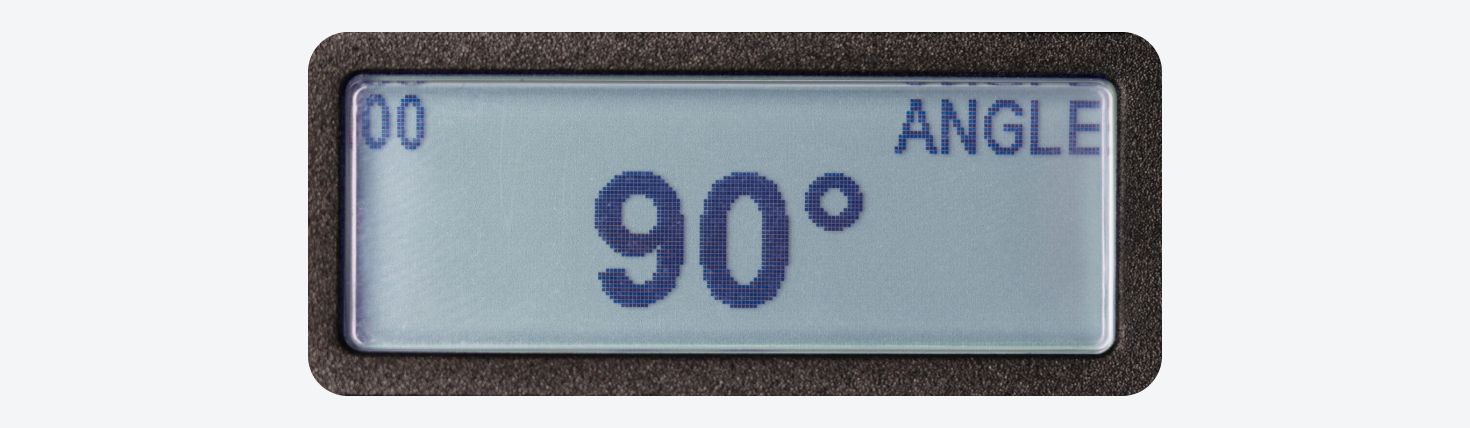

| Angle Range | 5° - 360º |

| Angle Calibration Test Points | 45°, 90°, 135°, 180º |

| Measurement Modes | Torque, Angle, Torque + Angle |

| Measuring Direction | Clockwise, Counterclockwise |

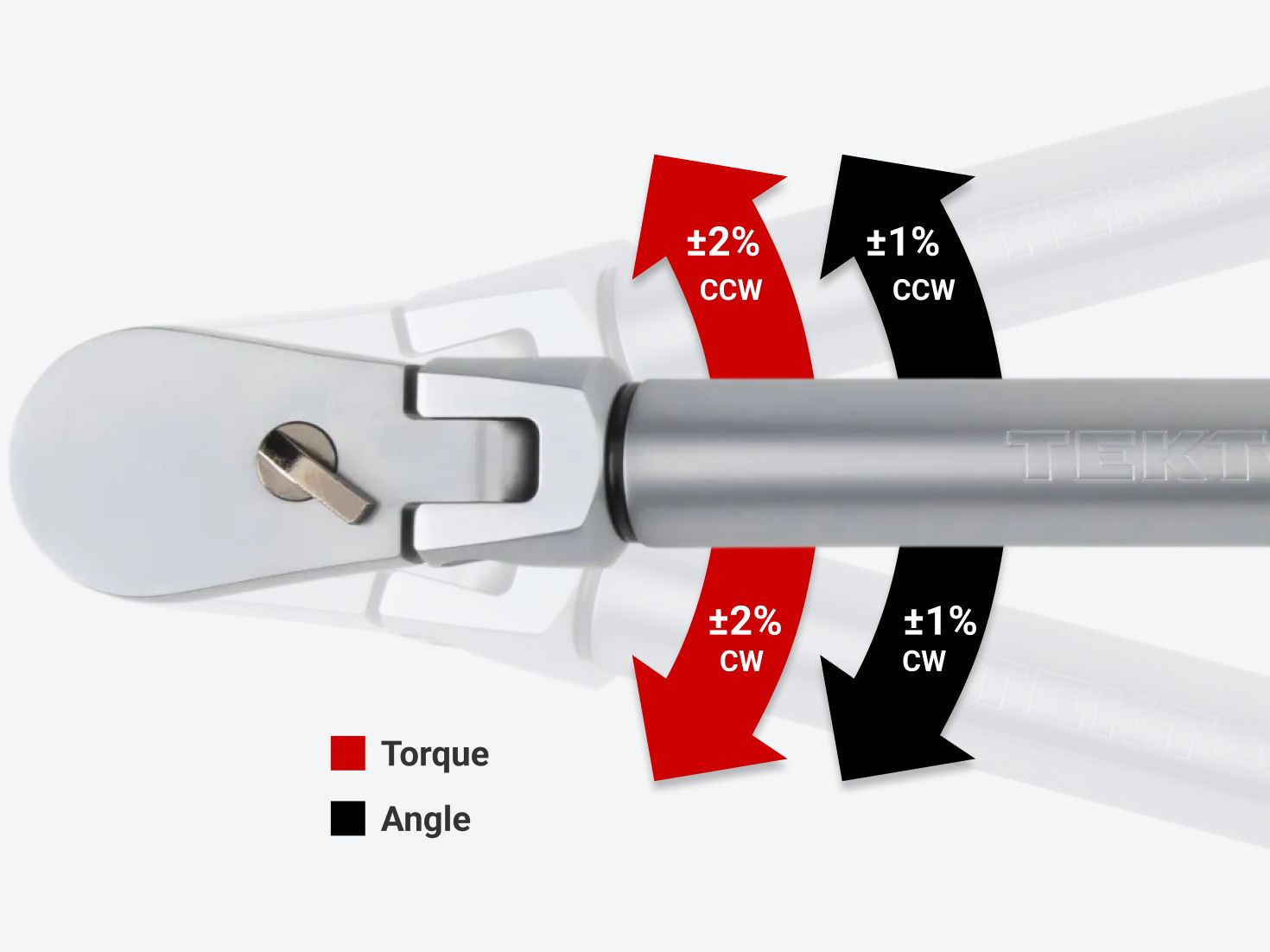

| Torque Accuracy | Within ±2% CW/CCW |

| Angle Accuracy | Within ±1% CW/CCW |

| Standards (meets or exceeds) | ISO 6789-1:2017 |

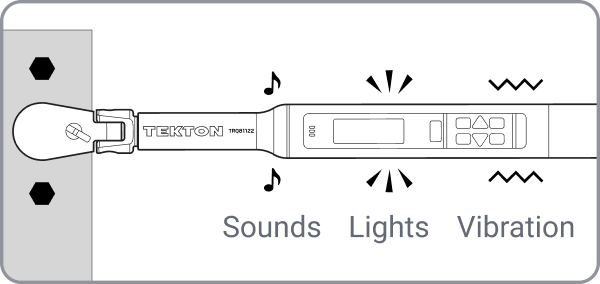

| Feedback | LCD, Lights, Sounds, Vibrations |

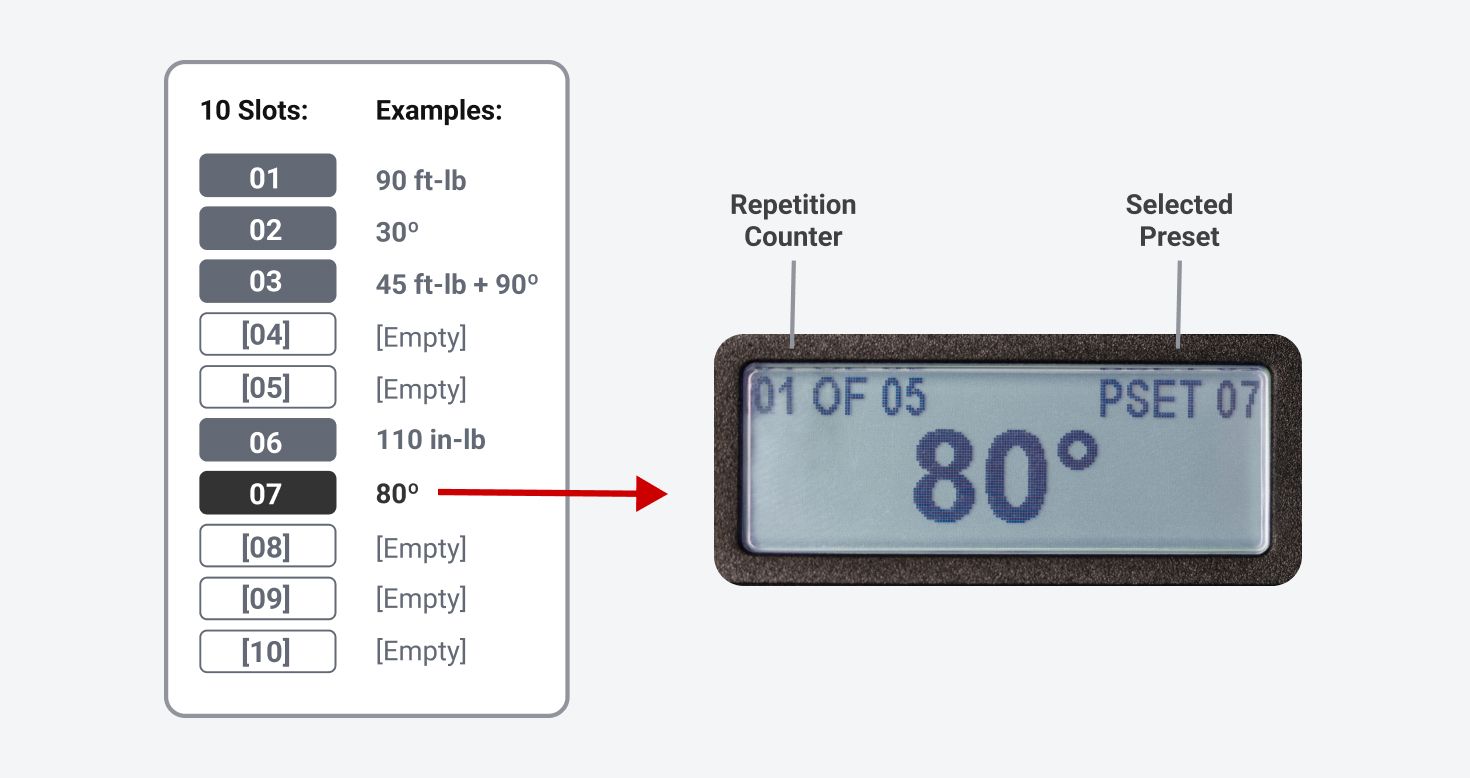

| Custom Presets | 10 Slots |

| History Records | Last 50 Peak Measurements |

| Length Offset | Up to ±15 in. / 381 mm |

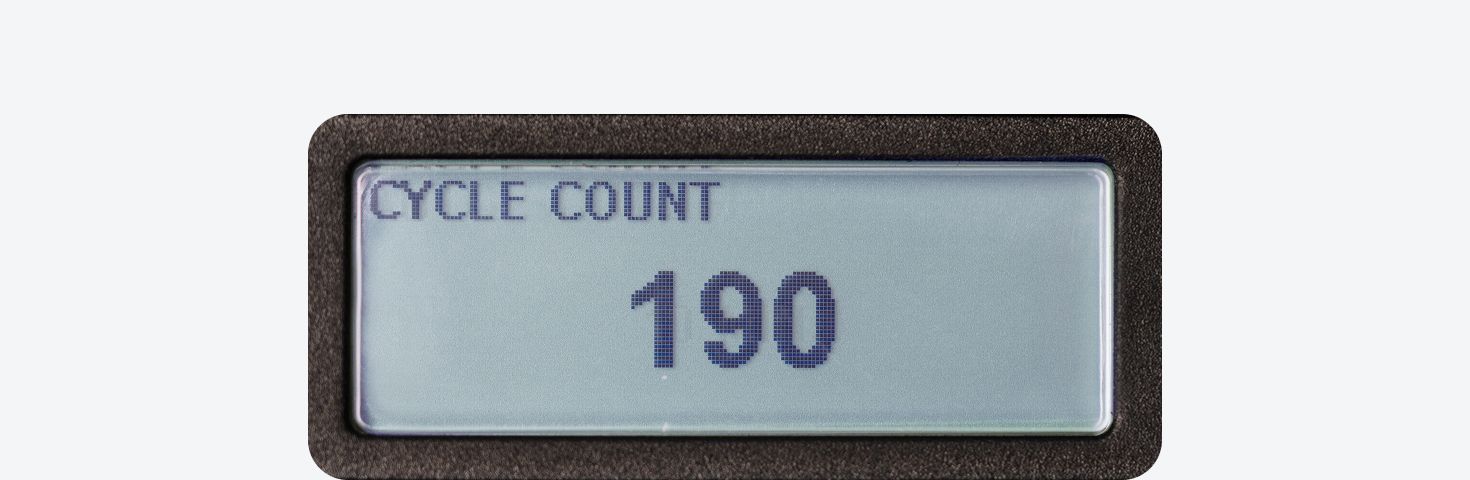

| Cycle Counters | Basic, Preset Repetitions, Total |

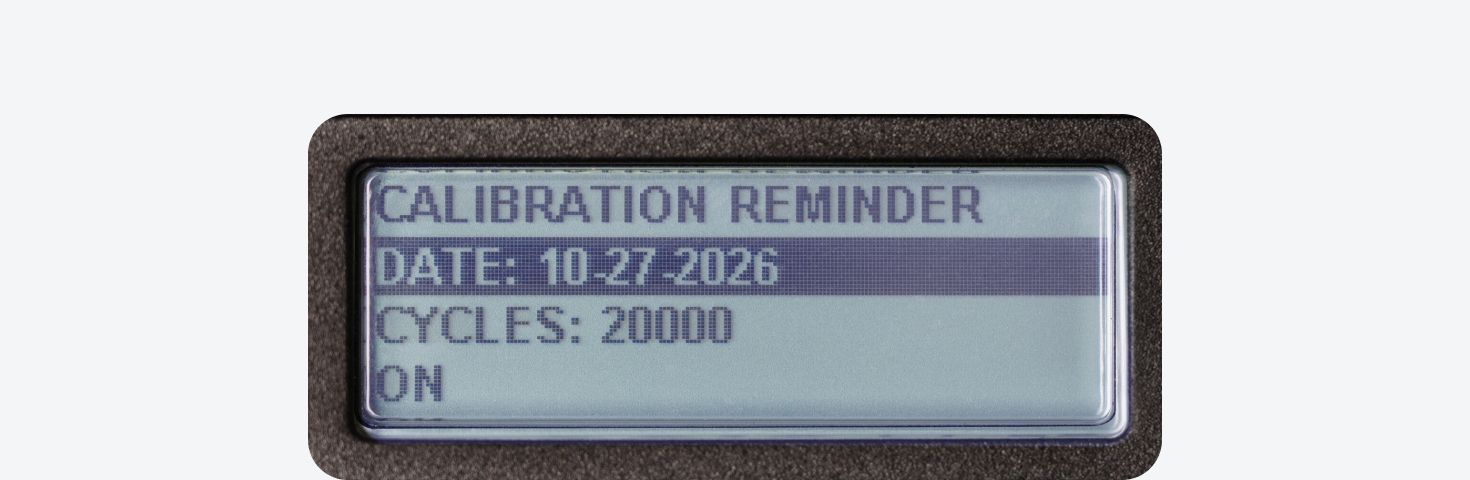

| Calibration Reminder | Date and/or Cycles |

| Language | English |

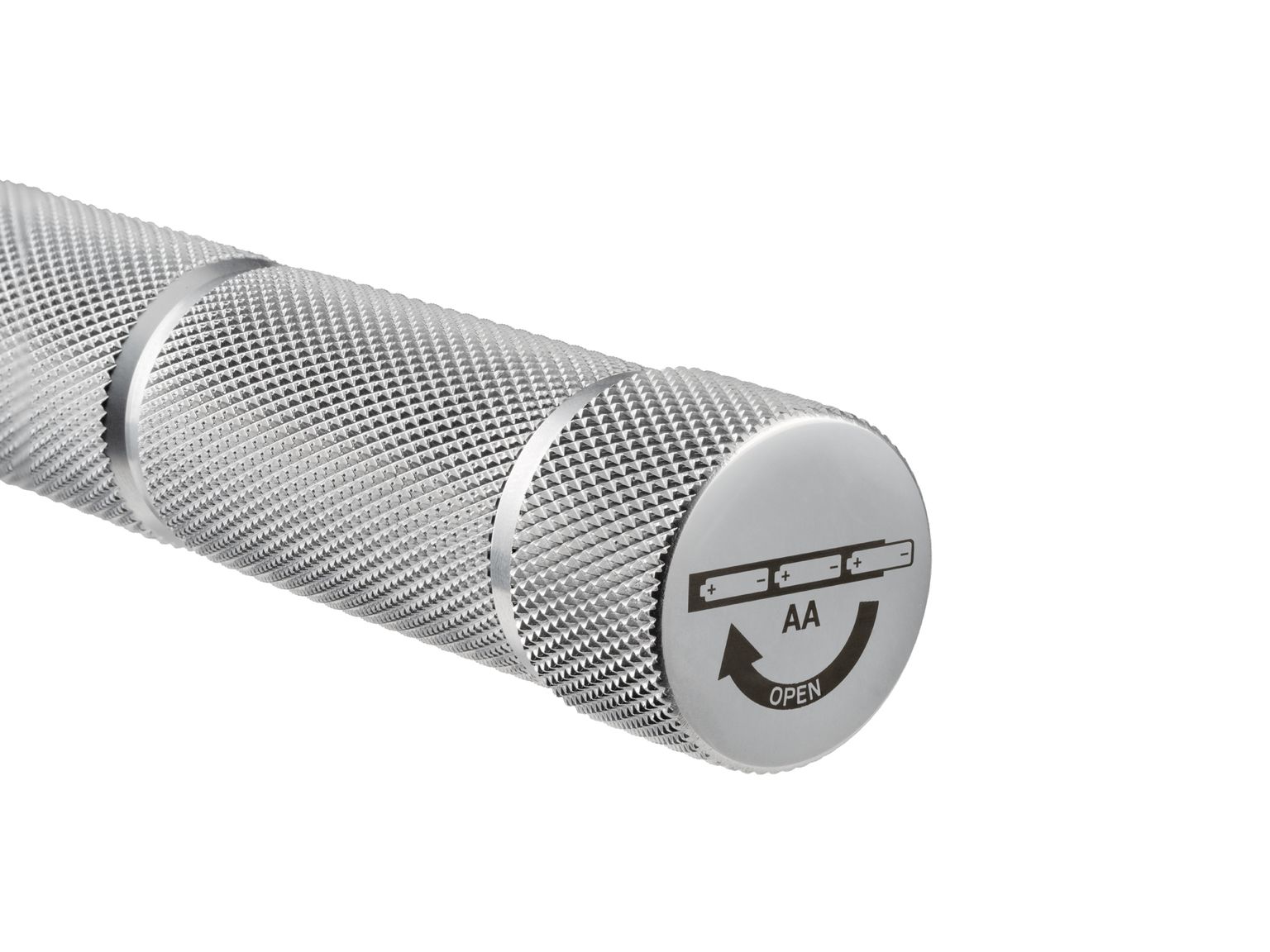

| Batteries | 3x AA 1.5 V (not included) |

| Working Length | 22.8 in. |

| Overall Length | 27.1 in. |

| Weight | 4.51 lb. |

| Country of Origin | Taiwan |

| Other Included Items |

|

Download Product Manual

Need to recertify your wrench’s calibration?

We are developing a recertification service for this torque wrench.

Subscribe to Tekton news to be notified when the service is available.

Details

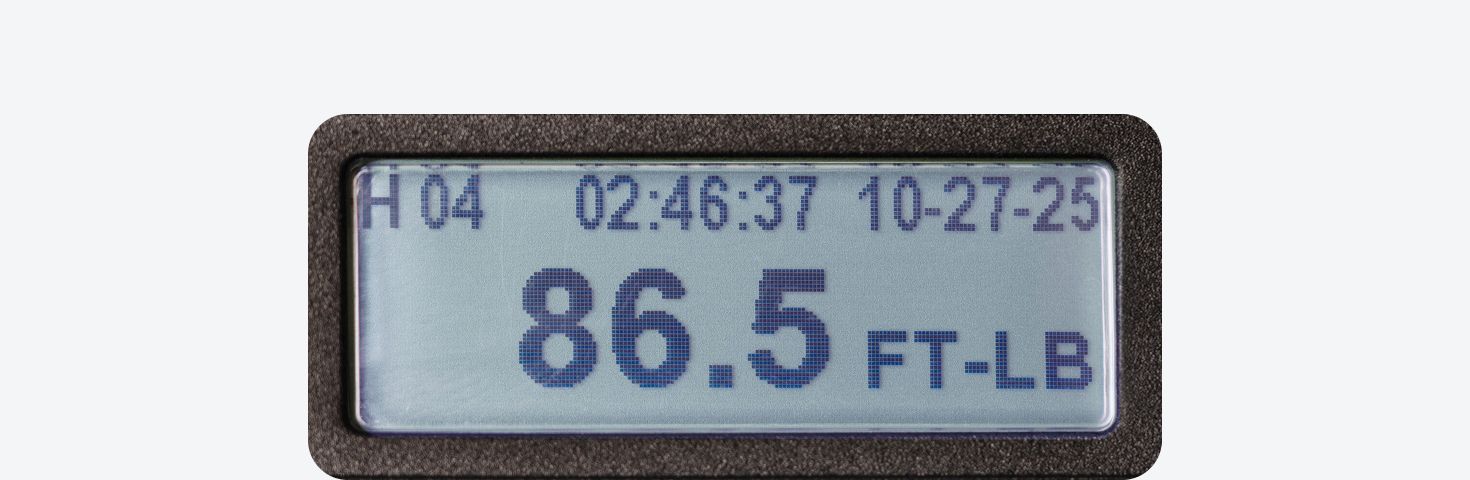

Simple Controls and Straightforward Operation

- Fast to power-on, select a mode, and set your target

- Large, clearly-labeled buttons

- Backlit LCD screen with bold fonts and clear contrast

- Real-time sensory feedback from sequential lights, beep patterns, and handle vibration

- Dedicated button for quickly selecting saved presets

- Simple navigation menus with quick escape button

Three Measurement Modes

Torque

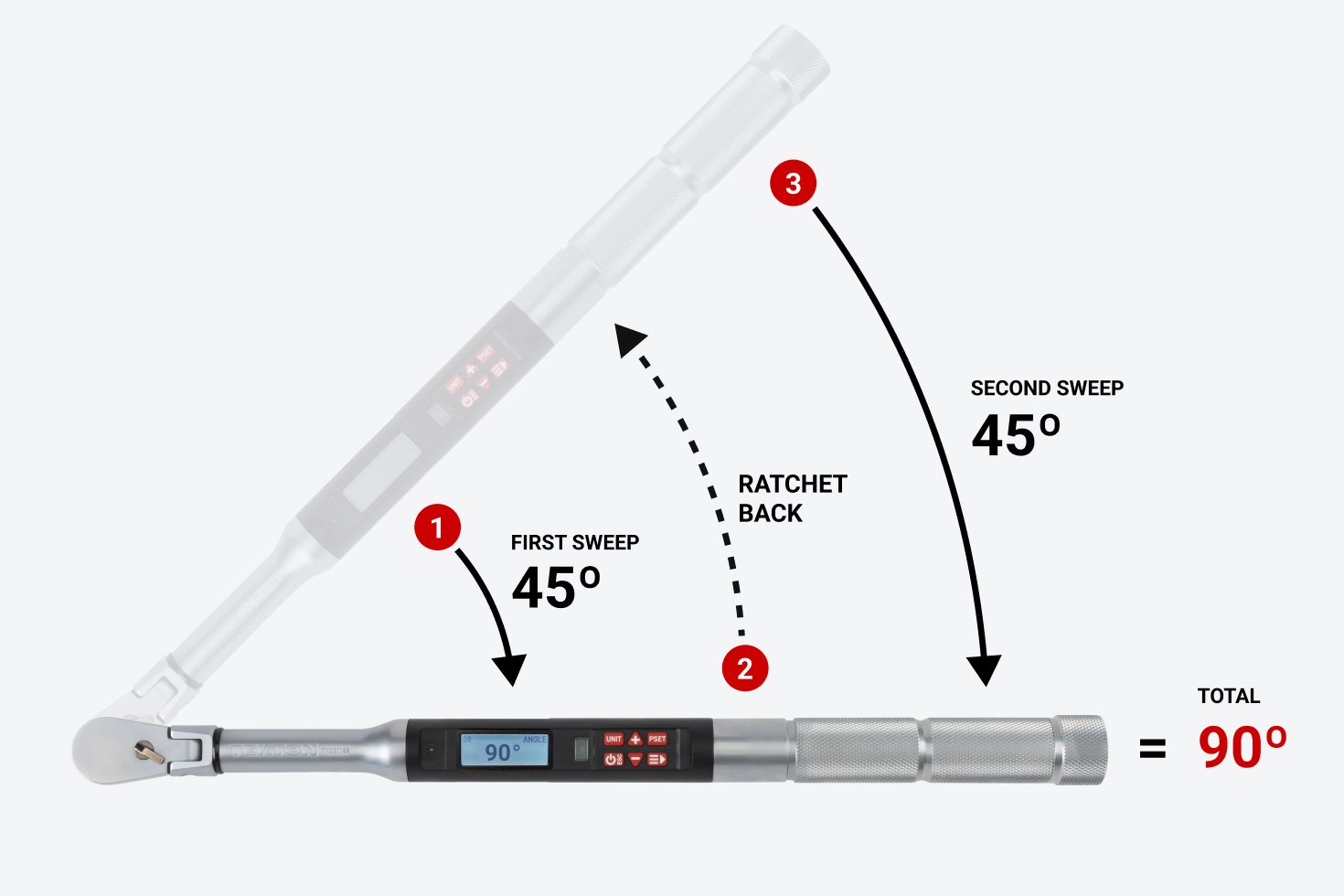

Angle

Torque + Angle

Lights, Sounds, and Vibration Feedback

Accumulate Angle in Multiple Sweeps

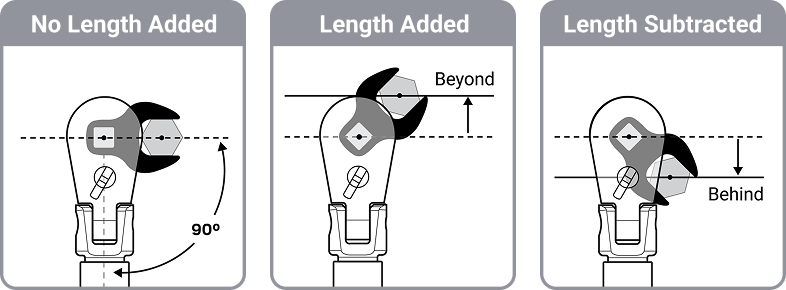

Easy Conversions for Length Offset

You can set a positive or negative offset, up to 15 in. or 381 mm. The offset can be used in all three measurement modes.

10 Customizable Presets with Repetition Counters

Additional Features

Saved History for the Last 50 Measurements

Shortcut to Recall the Last Peak Measurement

Set a Future Calibration Reminder

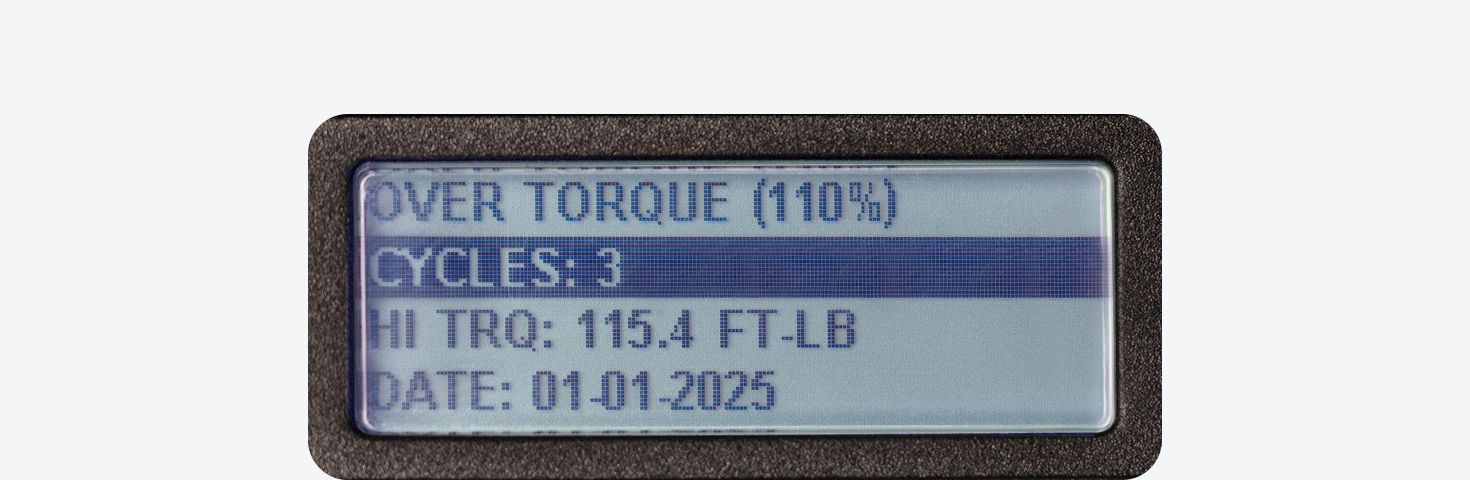

Over-Torque Warnings and History

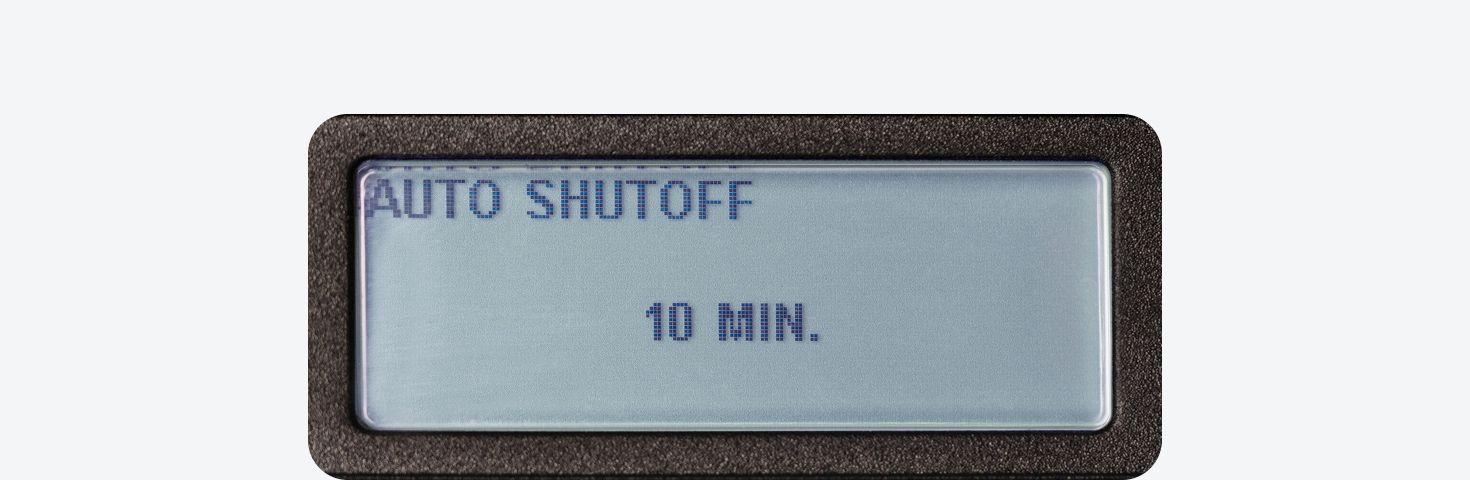

Power-Saving Auto-Shutoff Timer

Total Cycle Counter

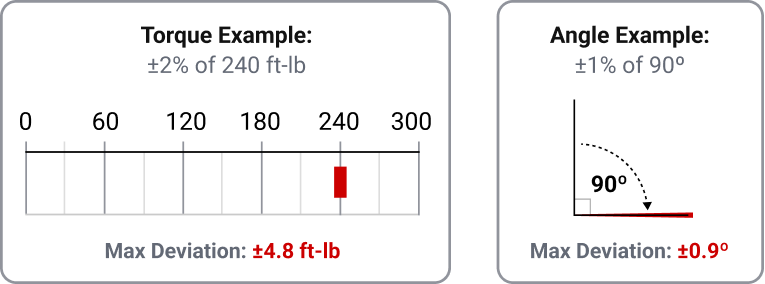

Accurate Within ±2% for Torque and ±1% for Angle

Full-Range Torque Calibration Using the ISO Standard

| Standard | ISO 6789-1:2017 | ASME B107.300-2021 |

|---|---|---|

| Set Points (Percentages are of maximum torque value) | Lowest Value 60% 100% | 20% 60% 100% |

| Accuracy | ±4% CW ±4% CCW | ±4% CW ±6% CCW |

| Readings Per Set Point | 5 | 3 |

This torque wrench is calibrated to the ISO standard for torque. The ASME standard is more commonly used, but the ISO requirements are stricter in a few key ways:

- ISO requires the lowest marked value on the scale to be tested. ASME starts testing at 20% of the range, which is often higher than the lowest marked value.

- ISO requires clockwise and counterclockwise tests to match, whereas ASME allows counterclockwise to be less precise.

- ISO requires 5 readings for each set point, whereas ASME only requires 3 readings for each.

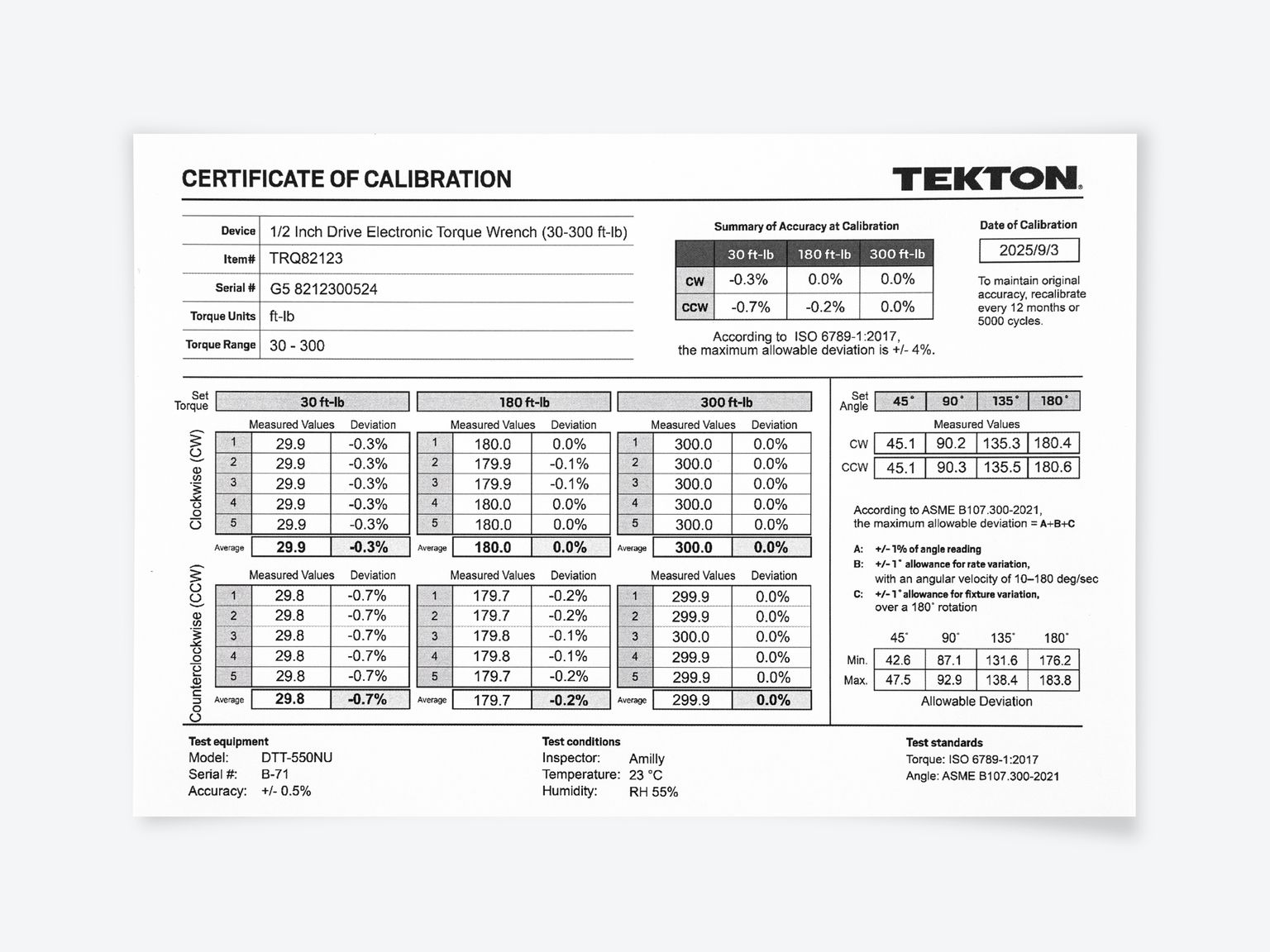

Serialized Certificate of Calibration

A. Serial number matching the engraving on the torque wrench

B. Torque tested at three set points (30, 180, 300 ft-lb)

C. Five torque tests for each set point in both directions

D. Test equipment and conditions

E. Quick summary of calibration tests

F. Angle tested in both directions at four set points (45º, 90º, 135º, 180º)

G. One angle test for each set point in both directions

H. Standards

90-Tooth Ratchet

4º Swing Arc Reduces Length of Travel

Having more teeth in the ratchet (B) results in less travel at the end of the wrench handle (D) between each tooth click.

1/2 Inch Drive (30 - 300 ft-lb)

#TRQ82123

| A. Overall Length | B. Tooth Count | C. Swing Arc | D. Length of Travel |

|---|---|---|---|

| 27.1 in. | 90 (Tekton) | 4° | 1.89 in. |

| 80 | 4.5° | 2.13 in. | |

| 72 | 5° | 2.36 in. | |

| 45 | 8° | 3.78 in. | |

| 36 | 10° | 4.72 in. | |

| 24 | 15° | 7.07 in. |

15-Degree Flex Head

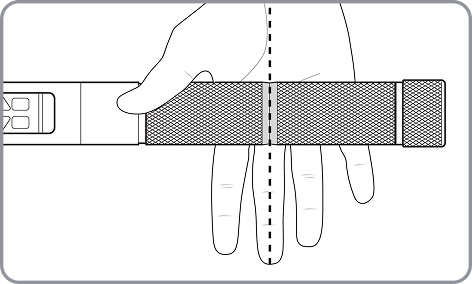

Coarse Knurling for a Secure Grip

Design and Components

Full-Featured Case

A. Product manual and certificate of calibration

B. Removable metal hinge pins

C. 1/2 inch to 3/8 inch drive reducer included

D. Hard polypropylene latches

E. Long-term storage slots for 3x AA Batteries

Removable Lid for Shallow Drawers

Top and Bottom Tracks Allow Stacking

Textured Surfaces Provide a Firm Grip

Compare Torque Wrenches

Accuracy: Within ±2% Torque, ±1% Angle

Directions: Clockwise, Counterclockwise

Tooth Count: 90 (4º Swing Arc)

Head Style: 15º Flex

Drive Sizes: 3/8, 1/2 in.

Feedback: LCD, Lights, Sounds, Vibration

Units: in-lb, ft-lb, Nm, kg-m

Accuracy: Within ±3%

Directions: Clockwise, Counterclockwise

Tooth Count: 90 (4º Swing Arc)

Head Style: Fixed

Drive Sizes: 1/4, 3/8, 1/2 in.

Feedback: Mechanical Click

Units: in-lb, ft-lb

Accuracy: Within ±4%

Directions: Clockwise

Tooth Count: 72 (5º Swing Arc)

Head Style: 10º Flex

Drive Sizes: 3/8, 1/2 in.

Feedback: Mechanical Click

Units: ft-lb, Nm

Specifications

1/2 Inch Drive 90-Tooth Flex Head Dual-Direction Electronic Torque Wrench (30 - 300 ft-lb)

| Country of Origin | Taiwan |

| Item Weight | 4.51 lb. |