SCREWDRIVERS

JIS vs Phillips: Understanding Tip Geometry, Myths, and Fastener Compatibility

November 7, 2025

Our new screwdrivers have Phillips tips that meet JIS standards (Japanese Industrial Standard). In this blog post, we’ll shed light on a highly confusing and widely misunderstood topic — what is the difference, if any, between JIS and Phillips drivers?

Cross-Tip Geometry (Normally Called Phillips)

In the United States, a cross-tip screwdriver is typically referred to as a “Phillips,” much like how mechanics use “Allen” to mean a hex key or “Crescent” to mean an adjustable wrench. Technically, the Phillips name refers to long-expired patented driver tip and fastener recess geometry that is now just a distant relative to the modern cross-tip geometry used in screwdrivers. In the 90 or so years since the original Phillips patent, there have been many attempts to improve the function of the geometry by adding extra gripping features as seen in designs like POZIDRIV® or PHILLIPS II® or ACR® PHILLIPS®. In short, Phillips and cross-tip mean the same thing.

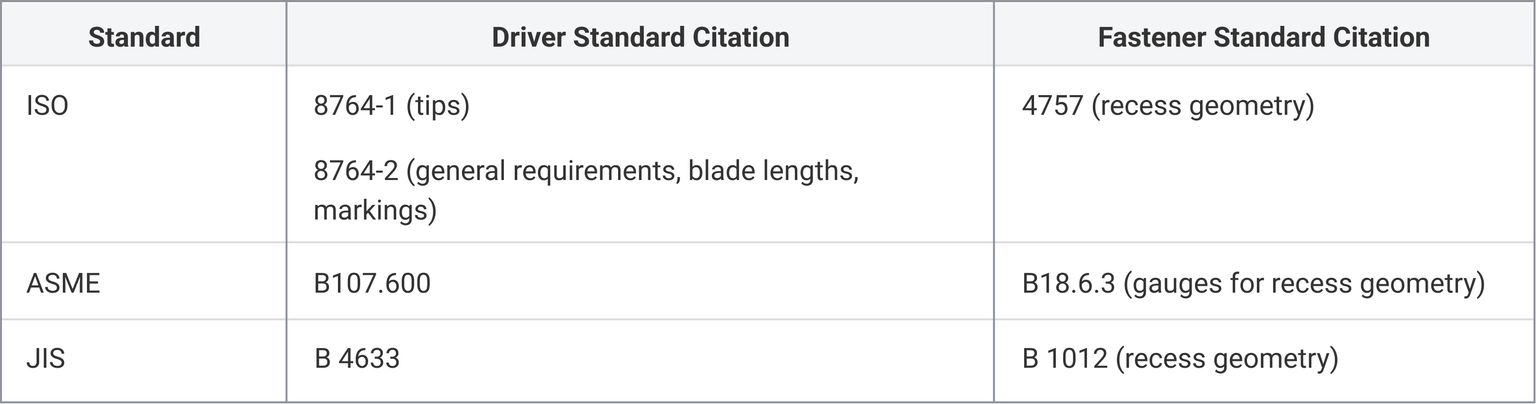

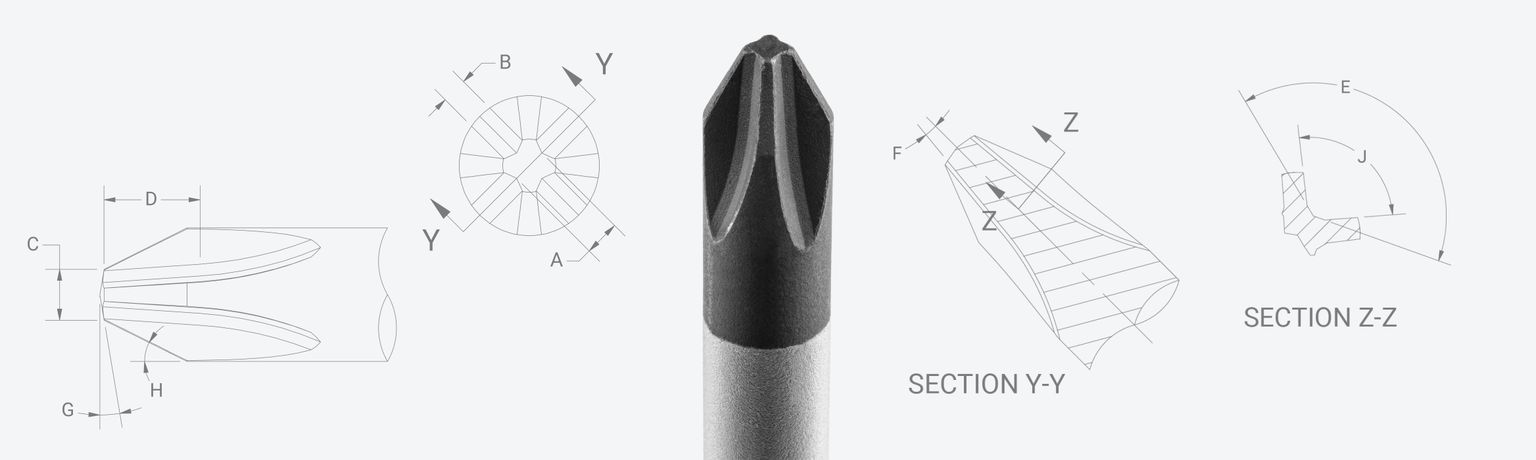

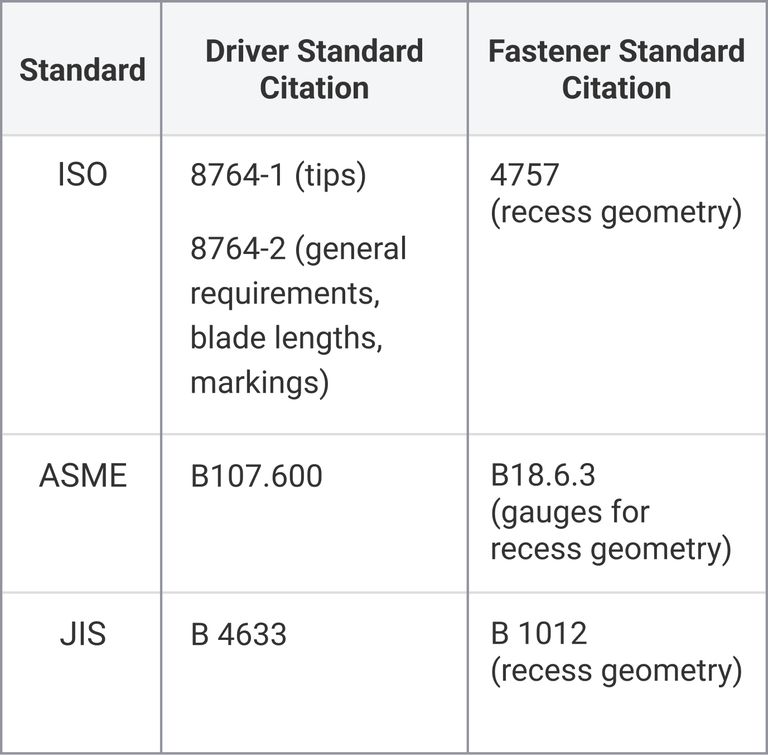

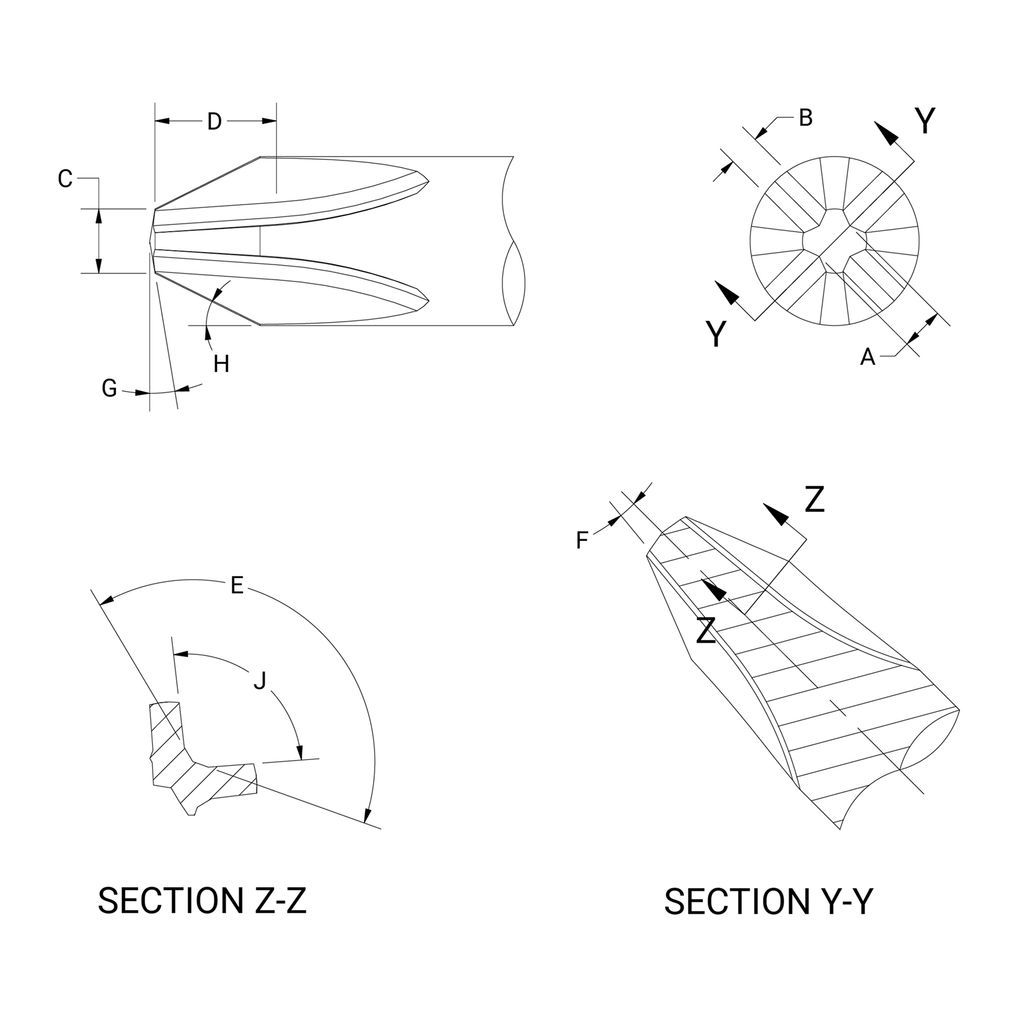

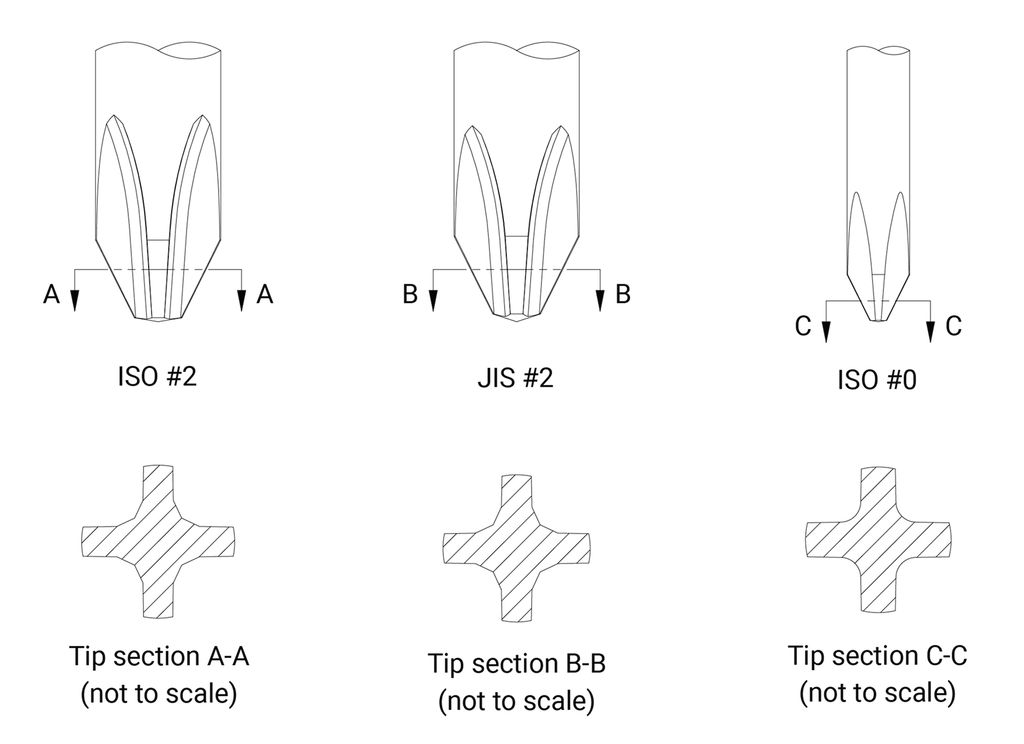

To manufacture a Phillips tip, we need a standard to follow. The standard provides the acceptable specifications according to the industrial group that made the standard. There is a standard for the driver tip and a parallel standard for the fastener recess that the tip goes into. Of course, these standards have to fit together.

The Phillips geometry is made today according to one of three standards:

- ASME, published by the American Society of Mechanical Engineers

- ISO, published by the International Organization for Standardization; or,

- JIS, published by the Japanese Standards Association.

In broad terms, ASME is typically the U.S. standard, ISO is typically a European or worldwide standard, and JIS is, of course, the Japanese standard. Another standard you may have heard about—DIN—comes from the German standards institute and refers to the Deutsches Institut für Normung. For the cross-tip geometry, DIN adopts the ISO standards and so we aren’t discussing it separately.

JIS “Compatibility”

This brings us to a major conclusion: JIS is not a tip type. JIS is the name of the Japanese standard for cross-tip or Phillips drivers, just like there is an American standard (ASME) and a European/international standard (ISO).

Our Phillips tips follow the ISO 8764-1 standard, which is compatible with the JIS standard B 4633. In fact, of the three main standards, ASME, ISO, and JIS, the least strict standard is JIS. As shown below, the JIS dimensions almost all fall within the ASME or ISO acceptable dimensions. Therefore, any Phillips screwdriver, such as our new Tekton Phillips screwdrivers, can be made to meet JIS standards. In fact, you should expect that all well-made drivers that meet the ASME or ISO standards will also meet the JIS standard.

But what about the common concern we see on user forums that Phillips drivers will damage or at least not work well on what users call “JIS” fasteners found on vintage motorcycles or bicycle components of Japanese origin? These concerns are based on a misunderstanding. Some people have a bad experience with Phillips drivers on Japanese fasteners for the same reason they could have a bad experience on any fastener:

- the screwdriver was damaged or made imprecisely; they needed a better screwdriver

- the fastener was damaged or made imprecisely; they needed a better fastener

- the user chose the wrong tip type

In summary, Phillips versus JIS is comparing apples and oranges. Phillips is about the shape. JIS is about the written standard. Are there any differences between the ASME, ISO, and JIS standards? Almost none, and the small differences are insignificant.

ASME Versus ISO Versus JIS for Cross-Tip or Phillips Screwdrivers

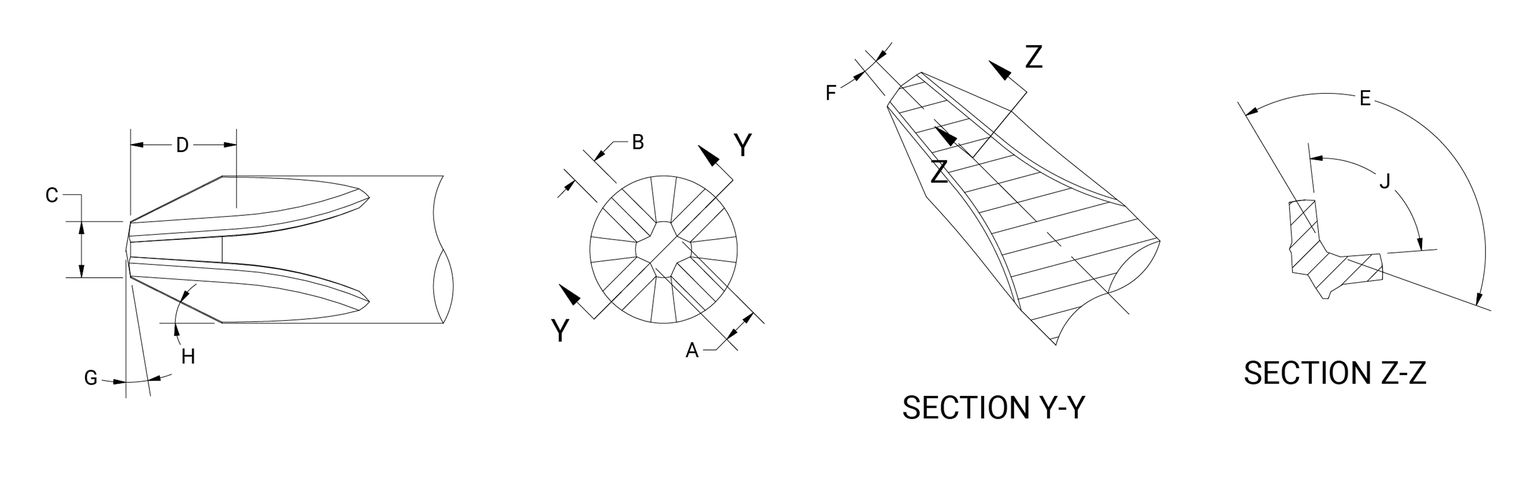

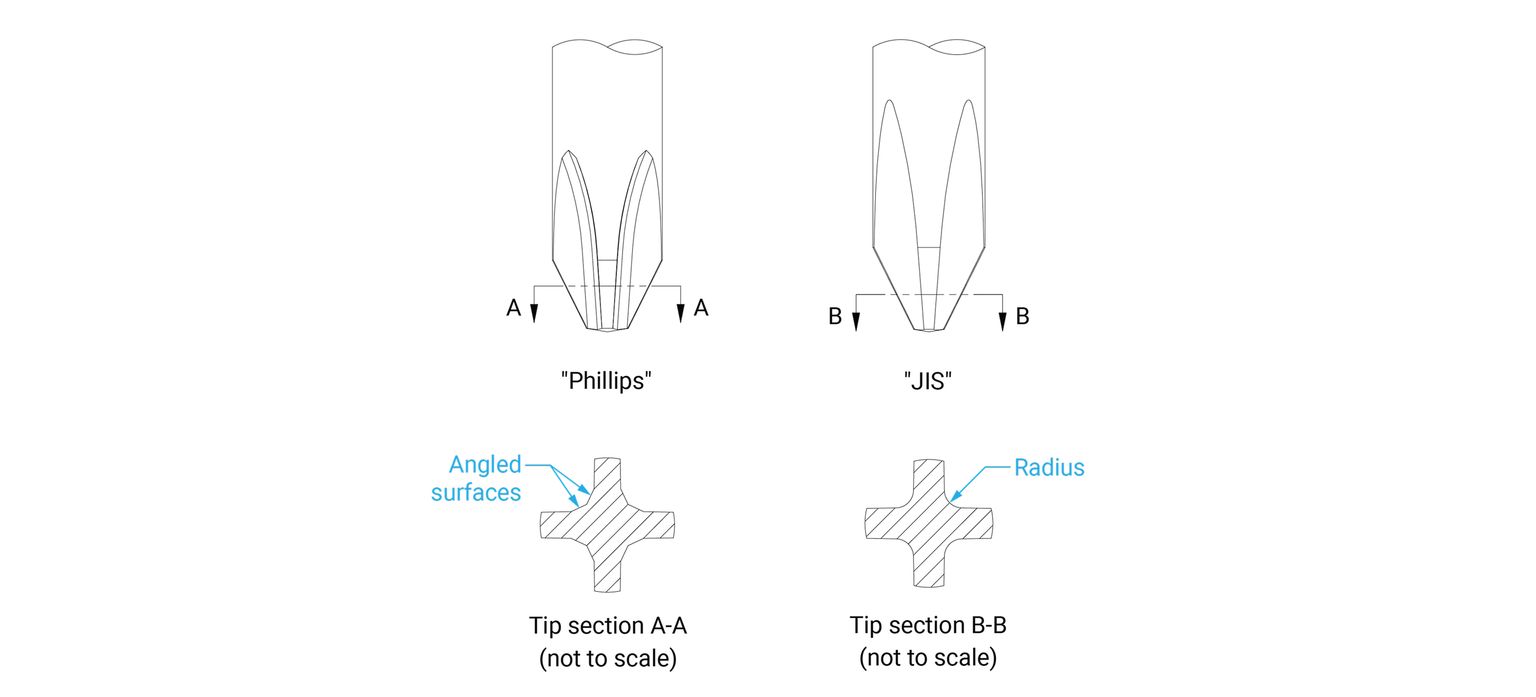

In the chart below, we show the standard dimensions for a Phillips #2 driver tip according to ASME, ISO, and JIS. In almost every dimension, the ASME or ISO driver requires a tighter range inside the JIS dimensions.

There are a few really minor differences:

First, the JIS standard allows shorter screwdriver tips (but doesn’t require them) compared to ASME or ISO. For example, on #2 Phillips, JIS says tips must be at least 3.70 mm, ISO says at least 4.37 mm, and ASME says at least 4.83 mm. In practice, what matters is that the tip of your driver end can reach into the screw recess. All of them can, and in fact JIS is the one that is limited in deep screw heads, if any are.

Second, ASME and ISO say that the angle at the very end of the tip can range from flat to slightly pointed (0–19 degrees), while JIS calls for a slightly pointed tip (17–19 degrees). Both standards should work in any normal cross-tip screw. In fact, what’s surprising here is that the standards refute the popular assumption that JIS specifies a flatter tip.

Now that we have discussed the geometry of a cross-tip or Phillips driver and how they are made according to an industry standard (ASME, ISO, or JIS), let’s address some common questions and myths:

Question 1: Isn’t it true that a Phillips screwdriver will damage older JIS screws from the 1970s and 1980s made to JIS standards?

Answer: No, not if the driver is made according to current ASME or ISO standards. We looked back at JIS literature as far as we could — to 1954, for which the standards were only available to us in Japanese. What we found is that, to the best of our knowledge, the JIS standard from 1954 is consistent with the modern JIS standard, which in turn aligns with ASME and ISO. This means that properly-made ASME/ISO Phillips drivers, like Tekton’s, will work on JIS-standard screws, both old and new.

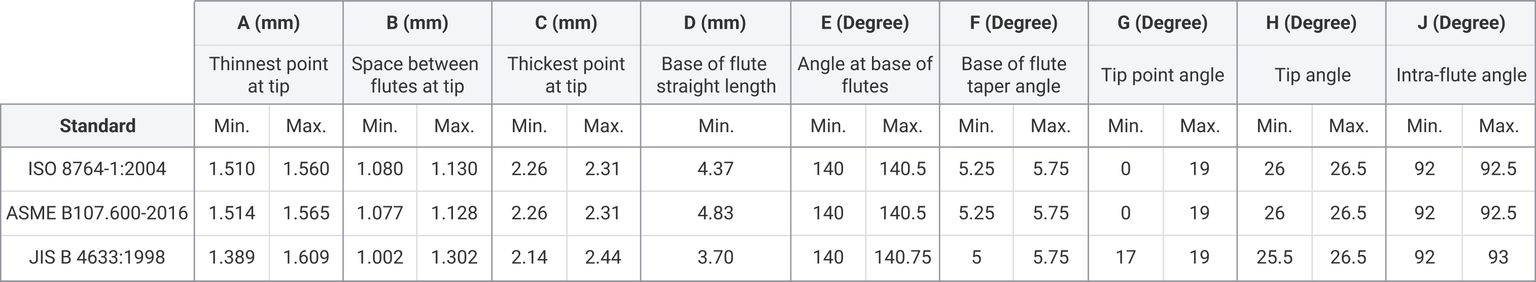

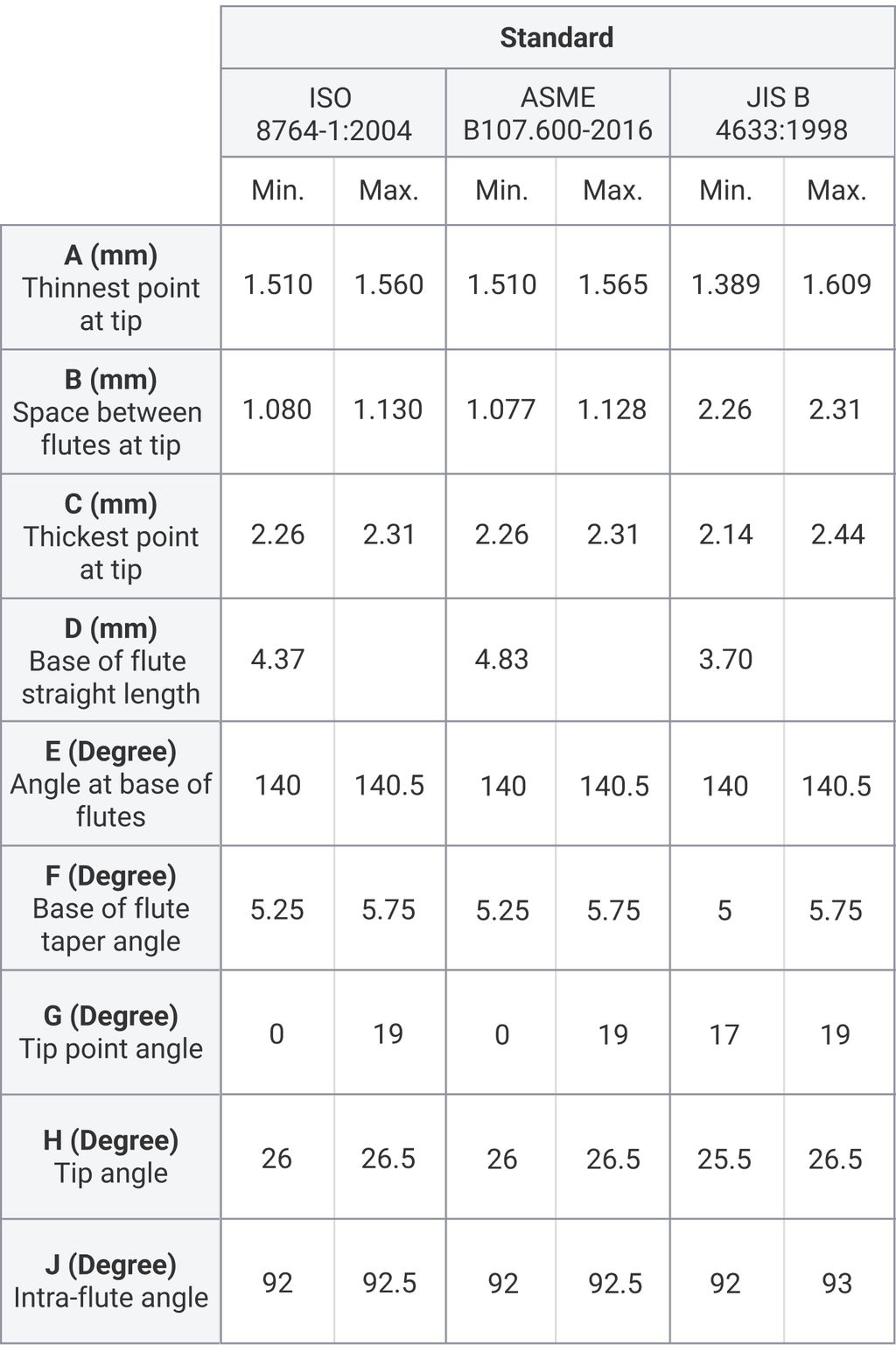

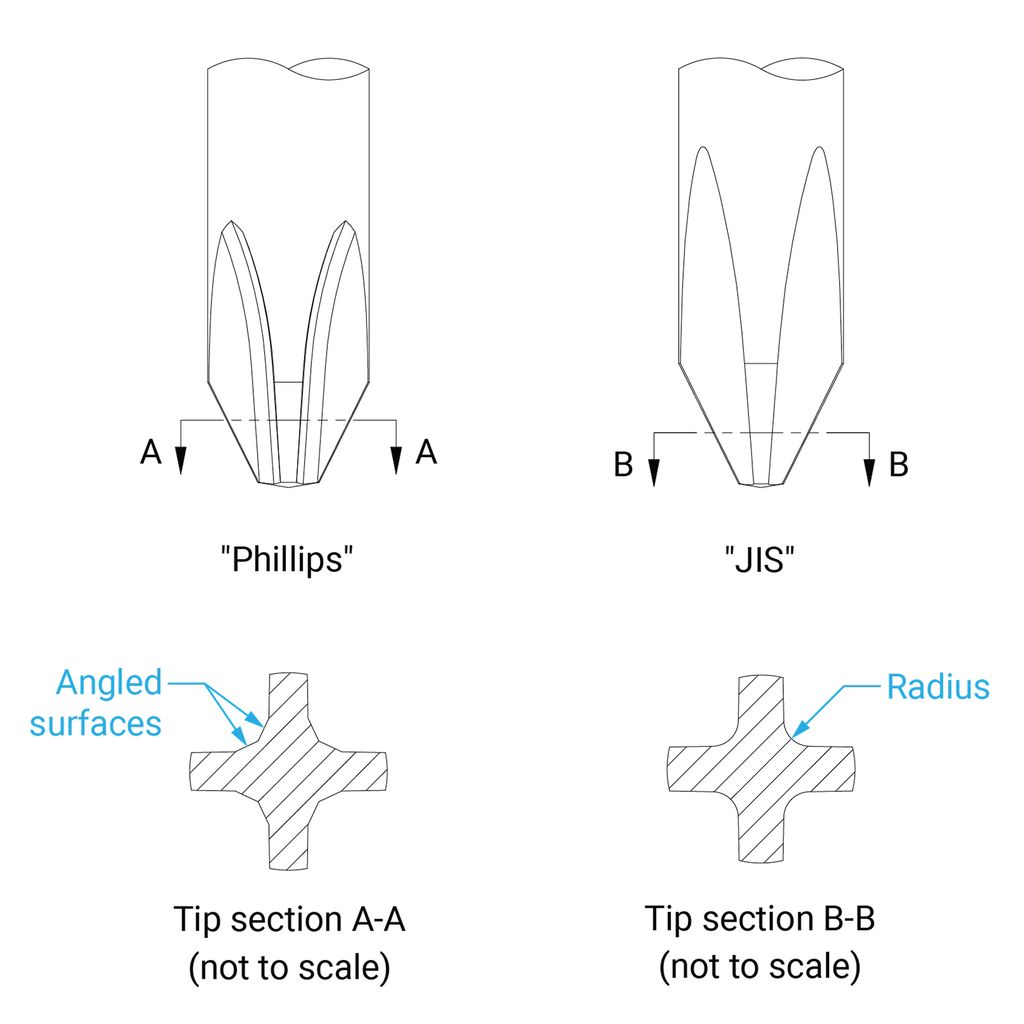

Question 2: What about all the online illustrations and images showing clearly that the geometry of a JIS driver is different than a Phillips driver?

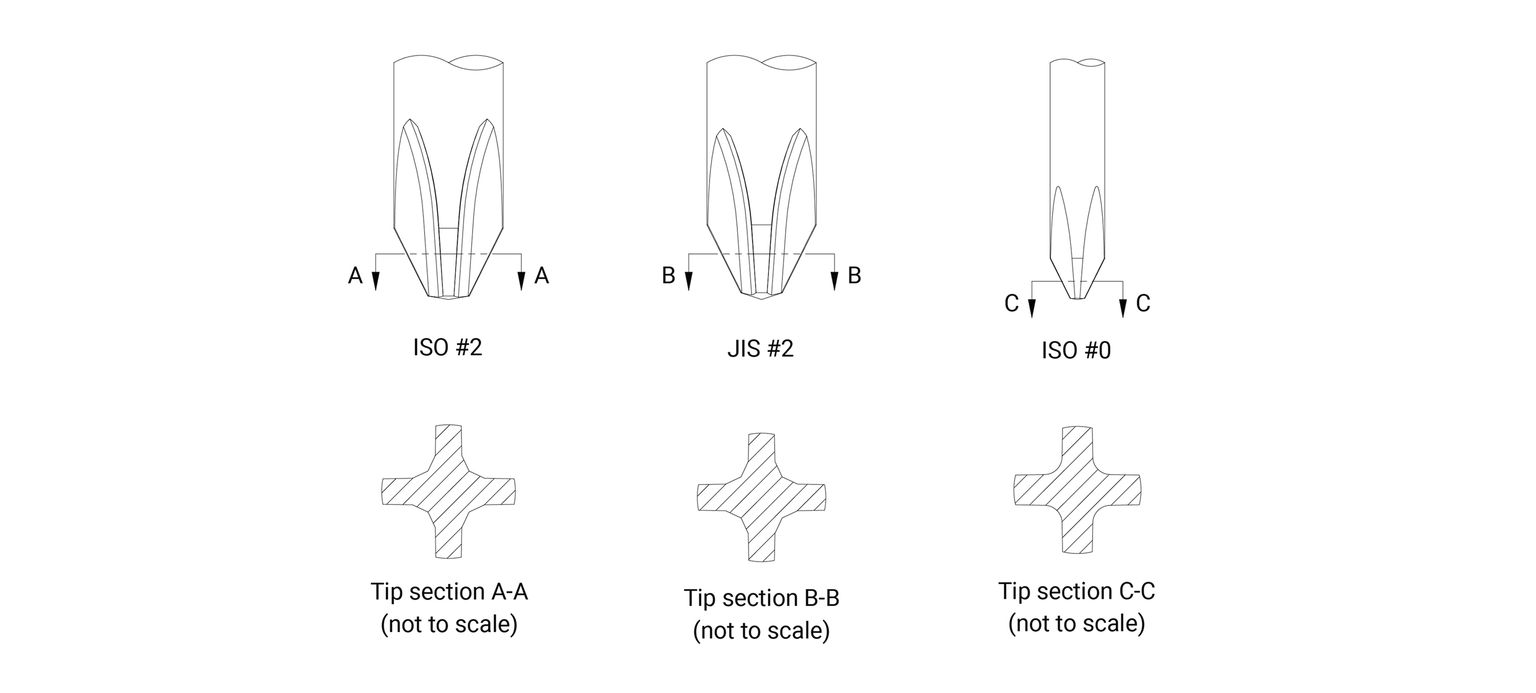

Answer: This is based on a misunderstanding that keeps getting passed around the internet. The illustrations are comparing different tip sizes, not different standards. We found examples of people claiming significant differences between Phillips and “JIS” driver tips, typically using an illustration like this as proof:

This example is not showing what people claim. It shows the difference between sizes #1–4 and size #0, rather than a difference between ISO/ASME and JIS standards. The #0 size, because it’s so small, does not have the additional angle at the base of the flutes — it has a small radius instead. This is true across ASME, ISO, and JIS. When you compare the same tip sizes — such as #2 versus #2 — the ASME, ISO, and JIS standards are compatible for Phillips drivers.

Question 3: If I buy from a Japanese manufacturer, will I get a better driver for JIS-standard screws?

Answer: Not necessarily. Again, there is no JIS tip type that is different from Phillips. There are a lot of great drivers made in Japan that fit screws really well. However, a standard works the same universally when used, no matter where you follow it. A driver from a Japanese manufacturer might work well in a cross-tip or Phillips screw because the driver (and the screw too) are well-made. It’s not because the screwdriver came from Japan or was made to the JIS standard. An ASME or ISO Phillips driver made well in Japan, Europe, the United States, or elsewhere will fit a JIS-standard screw.

Question 4: Do dots on a screw head require a JIS tip while everything else uses Phillips?

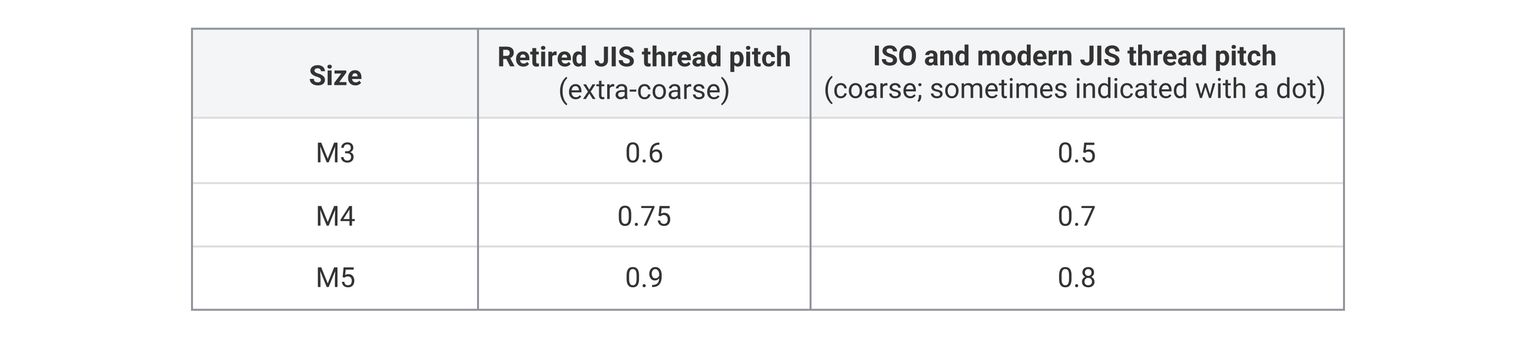

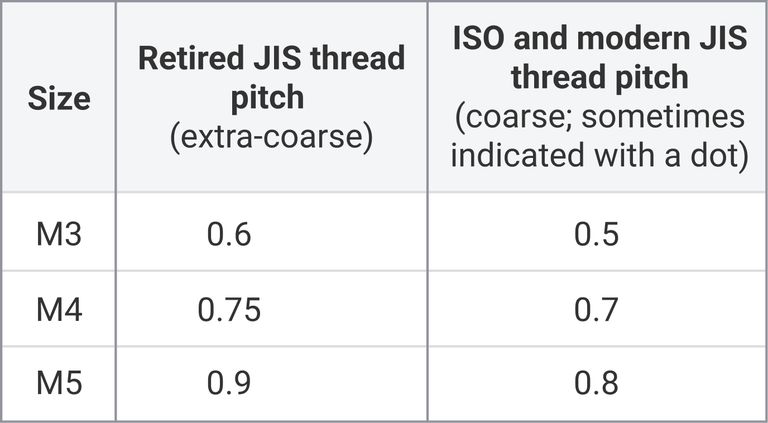

Answer: No, again, there is no such thing as a JIS tip that is different than a Phillips tip. The dot is actually an indicator of a JIS-standard screw thread pitch, which is not related to the screwdriver. In the mid-1960s, the JIS standards adopted the thread pitch specified by ISO and this dot was an indication to the industry and to service technicians of the new specifications. For example:

Only the fastener sizes that changed their thread pitch may have the dot. Many other JIS fasteners do not have the dot because they have standard thread pitches.

Question 5: Is Phillips geometry designed to “cam out” under pressure?

Answer: No. This is an often-repeated error. The original Phillips patents (US1908081A and US2046837A) show that camming out is not a design goal; on the contrary, the tip was designed to engage firmly and stay engaged. If camming out were a design goal, however, it would be the same design for all Philips drivers, whether made according to ASME, ISO, or JIS standards.

Trademark disclaimers

PHILLIPS®, POZIDRIV®, PHILLIPS II®, and ACR® are registered trademarks of The Phillips Screw Company.