Tap Click image to zoom in

Details

Our 1/2 Inch Drive Impact Socket Lineup

Our 1/2 inch drive 6-point impact socket lineup consists of shallow (previously called standard) and deep length sockets.

Two Size Markings

The size is marked in two ways on every socket—both as a high-visibility laser marking and a permanent stamped marking.

Full-Length Socket Well

While the overall socket is shallow length, the interior well extends fully into the socket, which allows for better fastener engagement in more situations.

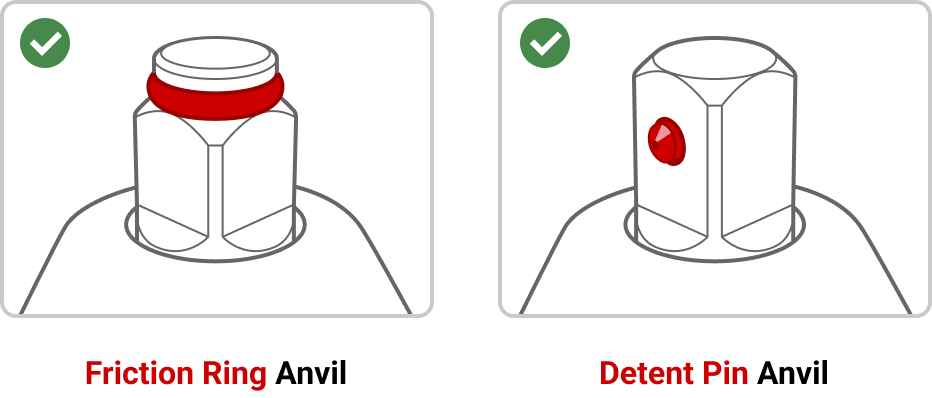

Drive Tool Retention

Sockets work with both types of anvils found on 1/2 inch drive impact wrenches:

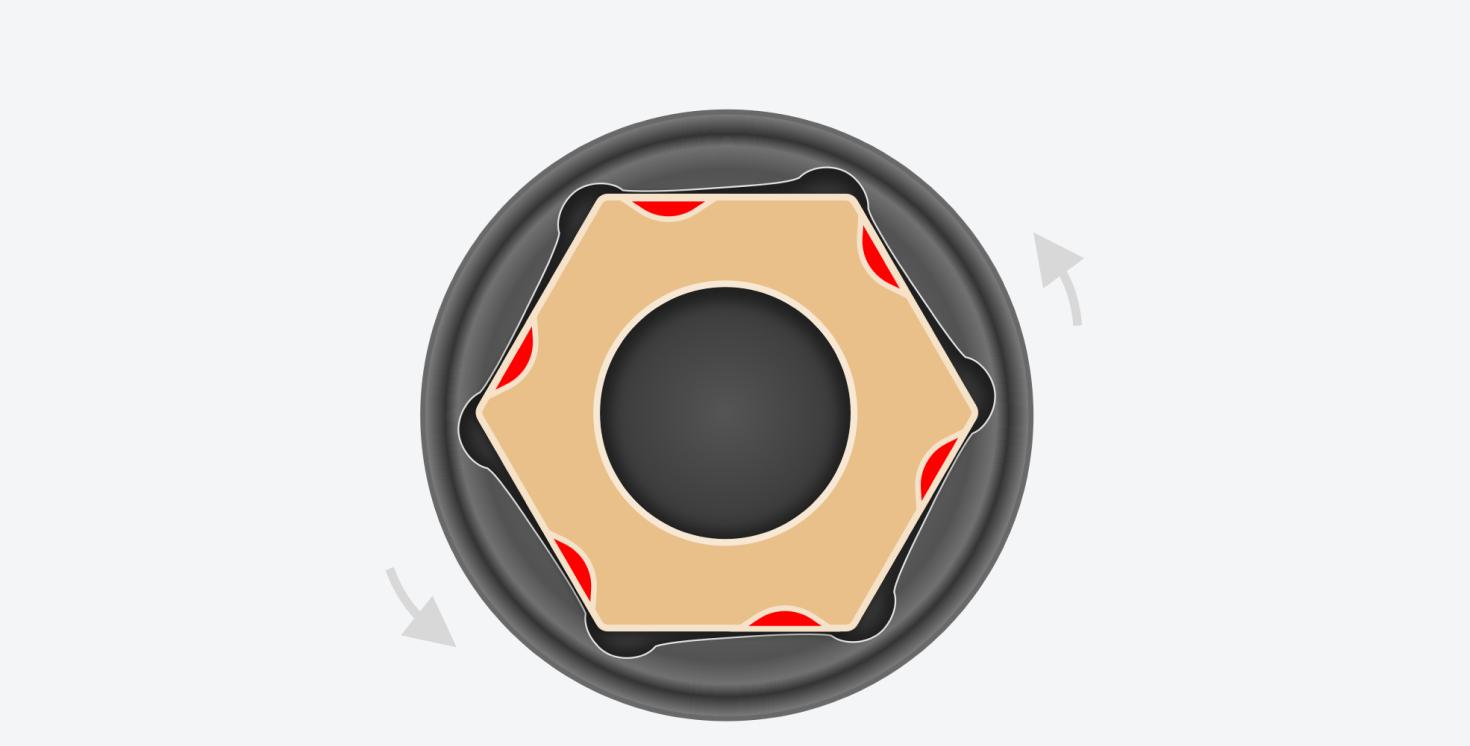

Prevents Fastener Round-Off

Radiused corners prevent fastener round-off by applying force to a fastener's flat sides, rather than its corners.

High-Performing Steel Alloys

Part by part, we choose the best combination of steel alloys, heat treating specifications, and forming processes to meet the highest performance requirements. Learn more

- 50BV30 Chromium-Vanadium (Cr-V)

- IN 5/16 - 1-1/4 in. sockets

- MM 8 - 32 mm sockets - 4140 Chromium-Molybdenum (Cr-Mo)

- IN 1-5/16 - 2 in. sockets

- MM 33 - 50 mm sockets

- Universal joint socket base - 6140 Chromium-Vanadium (Cr-V)

- 3, 6, and 10 inch extensions - 8660 Nickel-Chromium-Molybdenum (Ni-Cr-Mo)

- Adapter

- Reducer

- Universal joint ball/tang

All pieces have a corrosion-resistant manganese phosphate coating.

Specifications

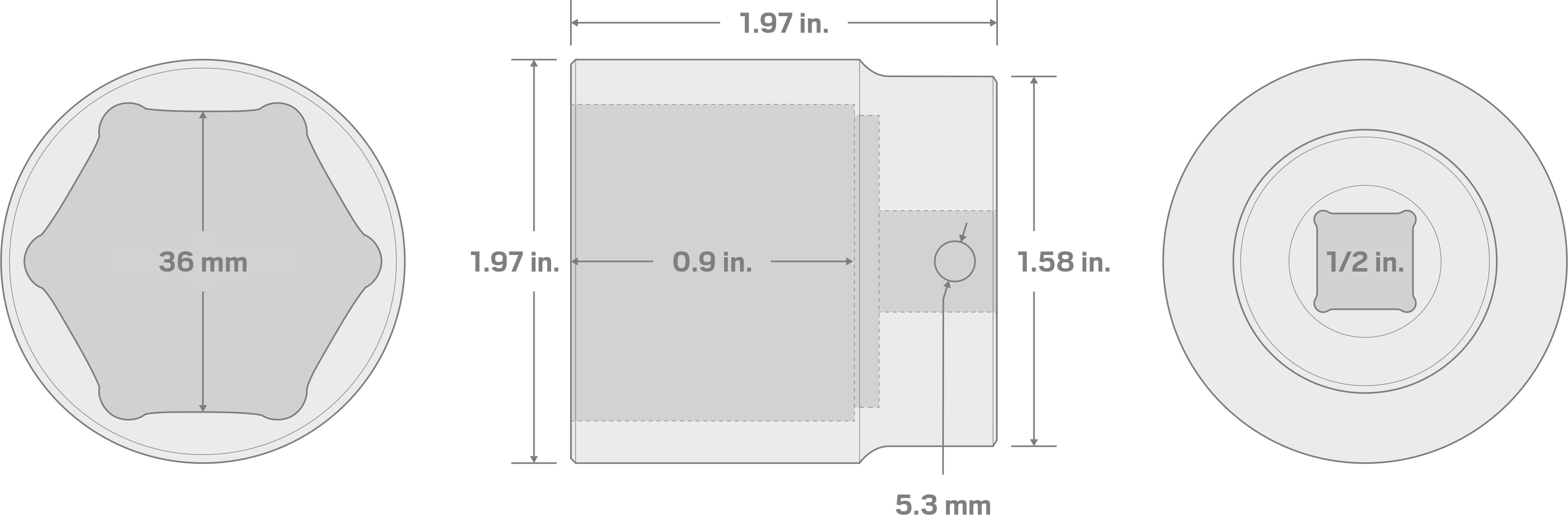

1/2 Inch Drive x 36 mm Shallow 6-Point Impact Socket

| Country of Origin | Taiwan |

| Item Weight | 0.8 lb. |